-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

DF series products are characterized by beautiful appearance, large air volume, and pulse back blowing dust removal. They adopt an integrated cabinet structure and beautiful appearance. They are specially designed for floating dust in the powder industry, chemical industry, metal processing industry, woodworking furniture industry, etc. Cost-effective. Equipped with Siemens motor and Japanese Toray polyester fiber filter cartridge to ensure high-level filtration accuracy and efficiency.

DF Series-Pulse Backflush Industrial Dust Collector

DF series of products with beautiful appearance, high winds, pulse cleaning dust is characteristic, with integrated cabinet structure, beautiful appearance, designed for powder industry, chemical industry, metal processing industry, woodworking and furniture industry and other floating dust design , Cost-effective. Equipped with Siemens motor and Japanese Toray polyester fiber filter cartridge to ensure high-level filtration accuracy and efficiency.

Boutique push

recommend

one

· Features·

1.Power unit, stable and reliable

1.Power unit, stable and reliable

The fan power unit is composed of a motor and a blade. The integrated compact design reduces the machine's floor space while ensuring negative air pressure.

Our SH-15 / SH-30 three-phase motors are Siemens branded, specially designed medium-pressure centrifugal impellers with excellent performance, low noise and good motion balance.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- -------

2.Filter cartridge filtration, high filtration accuracy

For the filtration system, a cartridge filter is used, and a Japanese Toray polyester fiber substrate is used. Standard configuration of PTFE membrane material, the filtration accuracy of dust with an equivalent diameter of 0.3 microns or more can reach more than 99%, and a filter cartridge material with higher filtration accuracy can be selected.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- --------

3. Pulse backflushing dust removal, good effect

3. Pulse backflushing dust removal, good effect

The cleaning system air gun manual cleaning method (as shown).

The DG series basic industrial dust collector needs manual dust cleaning operation. In order to avoid manual cleaning of the outer surface of the filter cartridge, which will cause dust to splash and form secondary pollution, we have a dust cleaning door on the back of the machine. Open the door and take an air gun to filter. The inner surface of the cylinder can be used for dust removal.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- --------

4. Electric control system, quality assurance

In terms of electrical systems, the main electrical control components are from internationally renowned brands-French Schneider products. The motor realizes independent control of the electrical box, built-in power sequence switch, thermal overload protection, phase loss, reverse phase and other phase sequence protection. The control panel is simple and generous, which can easily realize remote control, linkage control and other functions.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- --------

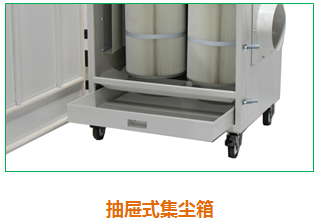

5. Drawer type dust box, practical and convenient

5. Drawer type dust box, practical and convenient

The dust collecting box adopts a drawer structure. After the dust is full, open the door panel, and the dust collecting box can be pulled out to clean up the dust. After the dust collecting box is completed, the dust collecting box can be sent in. Convenient, fast and practical.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- --------

two

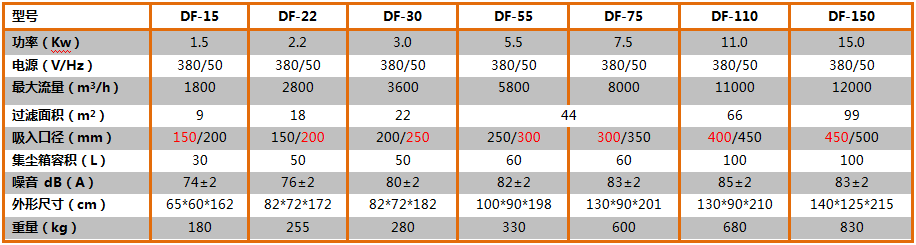

· Technical Parameters·

Three

· Typical Case·

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!