-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

————— ◆ Industrial exhaust gas analysis ◆ —————

>> Overview of rubber exhaust

Most of the exhaust pollutants in rubber exhaust gas come from the process of raw material polymerization and heat treatment of rubber production lines, which may contain a large amount of organic exhaust gases such as styrene, benzene, xylene, methyl ethyl ketone, aldehydes, sulfur compounds, nitrogen oxides and smoke Gas, which is accompanied by a certain temperature spread to the entire workshop and surrounding areas of the plant boundary, is a relatively polluted exhaust gas.

Rubber exhaust gas and rubber vulcanized flue gas are relatively harmful. The components of the exhaust gas contain malodorous substances, which drift along with the wind direction for a long distance and stay in the air for a long time. Cause various adverse effects. Therefore, it is necessary to carry out effective collection and purification treatment to ensure that the company's production runs well, improve the environment of the workshop and factory area, and meet national environmental protection requirements.

>> Composition of rubber exhaust gas

Rubber waste gas, the main components of which are tar and malodorous gases, non-methane total hydrocarbons. The odor components of rubber exhaust gas are complex and changeable, and can be roughly divided into 5 categories:

(1) Sulfur-containing compounds: such as H2S, SO2, thiols;

(2) Dust: such as carbon black;

(3) Chlorine-containing compounds: such as amides and indoles;

(4) hydrocarbons: such as alkanes, olefins, hydrocarbons, aromatic hydrocarbons;

(5) Organic matter containing oxygen, such as alcohol, phenol, aldehyde, ketone, organic acid, etc.

————— ◆ Processing effect standard ◆ —————

>> Design Principles

(1) Assist enterprises to adopt scientific and reasonable collection methods, and reduce gas volume as much as possible on the premise of achieving the collection effect.

(2) Actively and steadily adopt new technologies and new equipment, and adopt advanced and reliable pollution control technology in accordance with the status quo and management level of the enterprise, and strive to achieve stable operation, low cost, convenient management, and easy maintenance, so as to completely eliminate exhaust gas pollution and protect Environmental purpose. (2015-01-01)

(3) Properly resolve the pollutants generated during the construction and operation of the project to avoid secondary pollution.

(4) Strictly implement current national, local, and other codes, regulations, and standards on fire prevention, safety, health, and environmental protection.

(5) Select new, high-efficiency, low-noise equipment, pay attention to energy saving and consumption reduction.

(6) The overall plan layout strives to be compact, reasonably smooth, simple and practical. Minimize project occupation and construction difficulty.

(7) Strictly implement relevant national design codes and standards, and pay attention to fire protection and safety work. (GB16297-1996)

(8) Control industrial pollution in accordance with relevant national and local environmental protection laws, regulations and industrial policy requirements, and give full play to the social, environmental and economic benefits of construction projects.

>> Project scope and standards

1. Project scope

(1) The designer is responsible for the design, manufacture, installation, commissioning of the exhaust gas treatment equipment, and the design of the relevant pipelines.

(2) The designer is responsible for training the equipment operator of the owner unit.

(3) The owner unit is responsible for the supporting public works of the project, including power supply, water vapor, compressed air, circulating cooling water, etc.

2.Technical requirements

(1) The project does not consider land acquisition and uses the original factory land, which cannot seriously affect production;

(2) Adopt mature exhaust gas treatment technology, which requires technology to be safe, reliable, and economically reasonable;

(3) The disposal of by-products should not cause secondary pollution;

(4) All equipment and materials are new;

(5) Simple observation, monitoring and maintenance;

(6) Ensure personnel and equipment safety;

(7) Save energy, water and raw materials;

>> Emission Standard

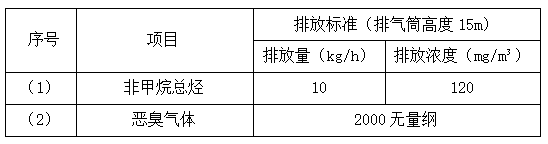

Exhaust gas emission standards implement secondary standards, refer to the "Integrated Emission Standards for Air Pollutants" (GB16297-1996) and "Emission Standards for Odor Pollutants" (GB14554-93). The exhaust gas emission standards are as follows:

————— ◆ Basis for program customization ◆ —————

(1) Project-related information provided by the owner

(2) Environmental Protection Law of the People's Republic of China (2015-01-01)

(3) Law of the People's Republic of China on the Prevention and Control of Atmospheric Pollution (2016-01-01)

(4) Ambient air quality standard (GB3095-2012)

(5) Decree No. 72 of the President of the People's Republic of China on the Law of the People's Republic of China on Cleaner Production Promotion

(6) "National 13th Five-Year Plan"

(7) "Integrated Emission Standard of Air Pollutants" (GB16297-1996)

(8) Emission Standard of Odor Pollutants (GB14554-1993)

(9) "Code for Environmental Protection Design of Construction Projects" (GB50483-2009)

(10) Design Code for Heating Ventilation and Air Conditioning (GB50019-2003)

(11) Code for Fire Protection of Building Design (GB50016-2014)

(12) Design Specification for Power Supply and Distribution System (GB50052-2009)

(13) "Control Standards for Emissions of Volatile Organic Compounds in Industrial Enterprises" DB13 / 2322-2016

(14) Guangzhou Puhua Environmental Technology Co., Ltd.'s comprehensive experience based on years of exhaust gas treatment project engineering and technology research and development

————— ◆ Exhaust gas system design ◆ —————

To be processedConsidering the operating cost and safety of rubber exhaust gas , the process route of the plan is planned to adopt "ventilation system (fan, collection hood, pipes) + absorption system (purification tower) + smoke and dust removal system (ionization trap) + deep purification system (adsorption and desorption) Attached + catalytic combustion) "is the core process to treat the exhaust gas. The process route diagram is as follows:

Ventilation system (fan, collecting hood, pipes) + absorption system (purification tower) + smoke and dust removal system (ionization trap) + deep purification system (adsorption and desorption + catalytic combustion) + fan + chimney

(1) The exhaust gas collected by the gas collection hood is introduced into the purification tower through the air duct, and the exhaust gas and water undergo full gas-liquid two-phase absorption and neutralization reaction through the filler layer. After the exhaust gas is purified, it enters the next process.

(2) The treated exhaust gas enters the ionization trap. When the flue gas passes, the dust and tar in the flue gas are ionized under the action of electric charge, move toward the charged metal wire and the pipe wall, and lose the electric charge. Under the action of gravity, it falls to the bottom of the ionization trap and flows out, so that the pollutants can be degraded and removed.

(3) The captured exhaust gas enters the deep purification system. When the activated carbon adsorber is close to saturation, the activated carbon adsorber is desorbed and desorbed with hot air to desorb the organic matter from the activated carbon. During the desorption process, the organic waste gas has been concentrated, and its concentration has been increased by dozens of times compared to the original, reaching more than 2000 ppm. The concentrated waste gas is sent to the catalytic decomposition device, and finally becomes CO2 and H2O. After deep purification, it will be discharged through fan chimney.

————— ◆ Cooperation Process ◆ —————