-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

DFK series products are characterized by high energy efficiency, high negative pressure, and high cost performance. They adopt an integrated cabinet structure and beautiful appearance. They are specially designed for laser cutting smoke, plasma cutting smoke and other floating dust. Customized high-efficiency impeller, imported brand polyester fiber filter cartridge, PTFE coating treatment, H13 grade high-level filtration accuracy and efficiency.

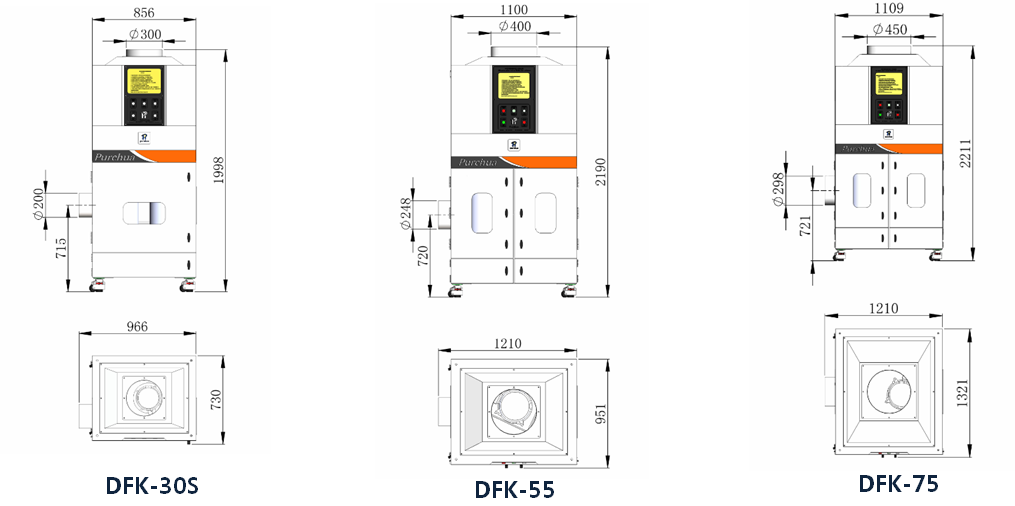

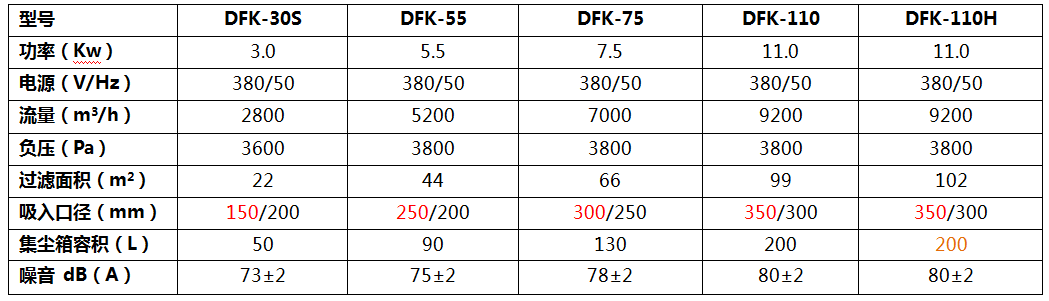

DFK Series High Efficiency Industrial Dust Collector

DFK series products are characterized by high energy efficiency, high negative pressure, and high cost performance. They adopt an integrated cabinet structure and beautiful appearance. They are specially designed for laser cutting smoke, plasma cutting smoke and other floating dust. Customized high-efficiency impeller, imported brand polyester fiber filter cartridge, PTFE coating treatment, H13 grade high-level filtration accuracy and efficiency.

Product Features of DFK Series High Efficiency Industrial Dust Collector

one

1. Siemens Motor, continuous escort

In terms of power system, the three-phase 380V voltage adopts Siemens three-phase asynchronous motors, equipped with special custom aluminum alloy impellers, the perfect combination of negative pressure and flow, stable operation, low failure rate, low noise, and can work continuously for 24 hours.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- -------

2.Filter cartridge filtration and quick release design

Filter cartridge type, polyester fiber material, high filtration accuracy, pleated design, large filtration area and small footprint.

The installation method of the filter cartridge adopts a quick-release structure design, which is very convenient for cleaning the filter cartridge. The filter cartridge can be taken out only by opening the end cover handle, which is convenient and practical.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- --------

3. Specially set dust cleaning door, no secondary pollution

The pneumatic pulse blowback system consists of a cylinder, an electromagnetic pulse valve, a PLC controller, and compressed air. One end of the pulse valve is connected to a compressed air storage cylinder and the other end is connected to an injection pipe. An exhaust valve is installed on the valve cover, and the exhaust valve is controlled by a pulse controller.

When there is no signal from the pulse controller, the pulse solenoid valve starts to work, and each time the ash cleaning is completed at about 0.1 to 0.3S, it is the high-pressure air that is sprayed at this instant to play a good ash cleaning effect. Air enters the filter cartridge at a high flow rate, causing the filter cartridge to expand rapidly, causing an impact vibration, causing the dust attached to the filter cartridge to be shaken off, and the fine dust adsorbed on the surface of the filter material is shaken into the dust collecting bucket under the action of the airflow .

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- --------

4. Quick-release filter cartridge design, very convenient for maintenance and cleaning

Adopting the Phuahua patent structure of the quick-release filter cartridge design, the installation and removal of the filter cartridge is very convenient, providing great convenience for manual cleaning of the filter, and the task of disassembling and installing the filter cartridge can be completed within 1 minute.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ---------

5. Humanized interactive interface and intelligent control system

The intelligent control system is designed with a pulse controller and a differential pressure sensor, which can realize multiple automation functions. It can use the combination of differential pressure control and timing control, combined intermittent backflush and continuous backflush. The combination has greatly improved the efficiency of pulse back blow ash cleaning, and the effect on refractory soot is more obvious.

There are power indicator, running indicator and dust-removal indicator on the panel, and the running status of the machine is clear at a glance. Built-in phase sequence protector, phase loss and reverse phase will be automatically protected, and the fan will not be reversed.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ---------

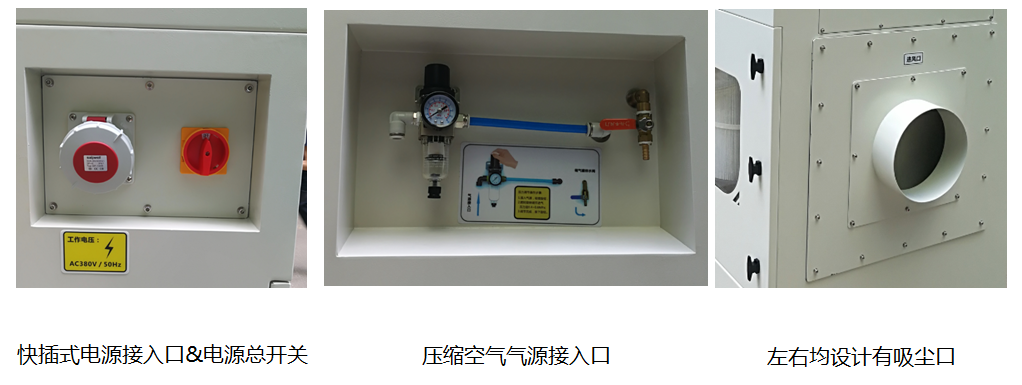

6. Focus on details and humanized design

Typical cases and product parameters

two

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!