-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

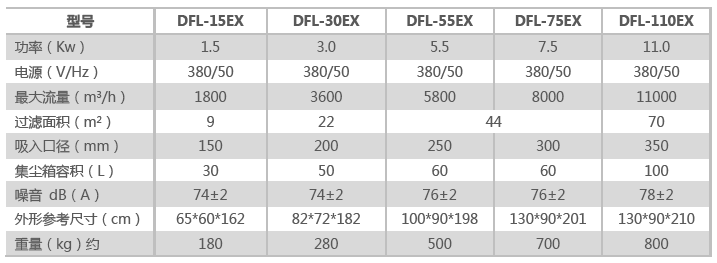

DFL-Ex series products are characterized by explosion-proof, high air volume, pulse back blowing dust removal, integrated cabinet structure, beautiful appearance, designed for floating dust in the powder industry, chemical industry, aluminum-magnesium metal processing industry, woodworking furniture industry, etc. The design is cost-effective. Electrical components including motors, electrical boxes, solenoid valves, etc. are all qualified products with explosion-proof certification, and filters are made of anti-static materials to

DFL-Ex series explosion-proof industrial dust collector

DFL-Ex series products are characterized by explosion-proof, high air volume, pulse back blowing dust removal, integrated cabinet structure, beautiful appearance, designed for floating dust in the powder industry, chemical industry, aluminum-magnesium metal processing industry, woodworking furniture industry, etc. The design is cost-effective. Electrical components including motors, electrical boxes, solenoid valves, etc. are all qualified products with explosion-proof certification, and filters are made of anti-static materials to prevent the generation of electrical sparks and static sparks.

Product recommendation

fine

Features

1. Explosion-proof motor, qualified certification

The power system consists of a motor and an air blade. It adopts a vertical motor structure and an integrated compact design, which reduces the machine's floor space while ensuring the negative air pressure.

The explosion-proof motor we use adopts the Wannan brand, and its explosion-proof grade: Ex tD A21 IP65 T135 ℃.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- -------

2.Explosion-proof electric box to eliminate hidden dangers of electrical sparks

The control system adopts explosion-proof electric box, internal AC contactor and thermal overload adopt Schneider electric components.

Explosion-proof explosion-proof electrical box, explosion-proof mark: Ex d Ⅱ BT6 / Ex tD A21 IP65 T80 ℃ (double explosion-proof certification of gas and dust).

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- -------

3. Anti-static filter to eliminate the hidden danger of static sparks

For the filtration system, a cartridge filter is used, and a Japanese Toray polyester fiber substrate is used. Standard configuration of PTFE membrane material, the filtration accuracy of dust with an equivalent diameter of 0.3 microns or more can reach more than 99%, and a filter cartridge material with higher filtration accuracy can be selected.

The surface is coated with aluminum film, with good antistatic performance, and the surface resistance is ≤106Ω.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- -------

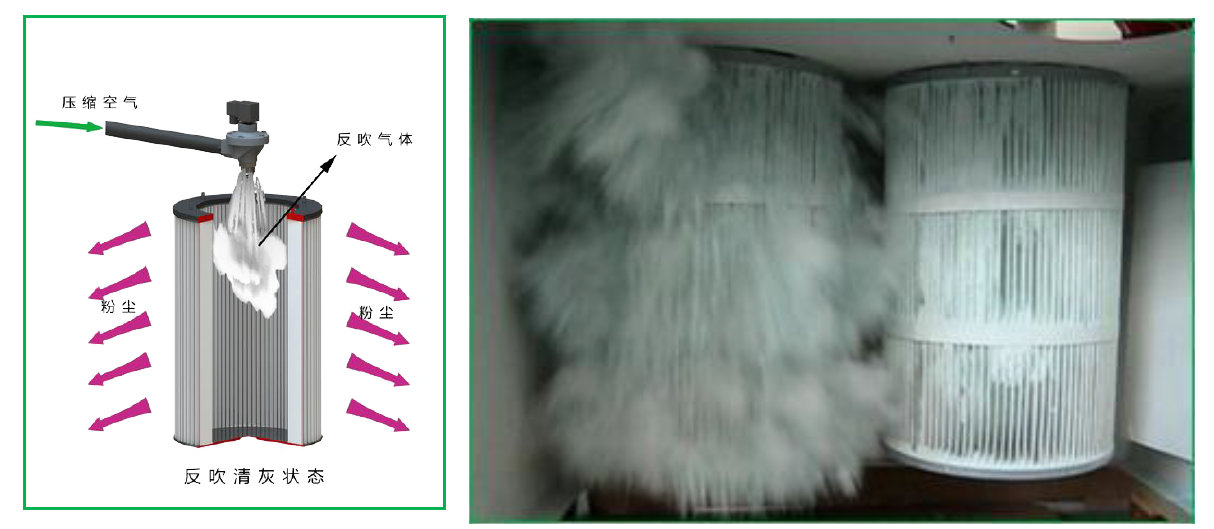

4. Pulse backflushing and dust removal, good effect

The pneumatic pulse blowback system consists of a cylinder, an electromagnetic pulse valve, a pulse controller, and compressed air. One end of the pulse valve is connected to a compressed air storage cylinder and the other end is connected to an injection pipe. An exhaust valve is installed on the valve cover, and the exhaust valve is controlled by a pulse controller.

When there is no signal from the pulse controller, the pulse solenoid valve starts to work, and each time the ash cleaning is completed at about 0.1 to 0.3S, it is the high-pressure air that is sprayed at this instant to play a good ash cleaning effect. Air enters the filter cartridge at a high flow rate, causing the filter cartridge to expand rapidly, causing an impact vibration, causing the dust attached to the filter cartridge to be shaken off, and the fine dust adsorbed on the surface of the filter material is shaken into the dust collecting bucket under the action of the airflow .

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- -------

5. Explosion-proof configuration of pulse backflush system

Using the best filter cartridge cleaning technology so far, automatic pulse back-blow cleaning, and combined with the specially developed spiral injection technology, the cleaning area covers the entire surface of the filter cartridge, and there is no cleaning blind area.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- -------

6, standard vent

6, standard vent

DFL-EX explosion-proof industrial dust collector uses a vent diaphragm device, which can blast at a specified temperature and pressure, release pressure, protect the safety of pressure-containing equipment and the safety of the operator's life, and avoid The environment used is more damaged. The burst pressure of the venting diaphragm is 0.01Mpa, and there is a professional certificate identification card.

The vent diaphragm is located at the rear of the machine. This diaphragm has good rigidity and fatigue resistance, and will not be prematurely damaged due to continuous operation of the machine; once a dust explosion occurs, the explosion-proof diaphragm will quickly rupture and release pressure, preventing the machine from secondary explosion.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- -------

Typical application cases and parameters

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!