-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

The welding fumes captured by multiple stations are concentrated into the dedusting and purifying host through the pipeline for treatment. The cleaned air is discharged from the cupola, and the filtered dust is automatically cleaned by the equipment and entered the ash bucket through the ash discharge valve. The capture device includes a suction arm, a top suction hood / side suction hood, a workshop, etc., which can be determined according to the actual situation on site.

Ceiling-mounted suction arm and top smoking purification system

At present, there are two main methods for the management of smoke and dust in the welding workshop of the manufacturing industry: one is the capture method at the source. The dust is sucked into the dust removal system through the suction arm or the capture cover at the source. This method is more limited for large workpieces, complex shapes, and frequent work movements. The second is the overall plant ventilation filtering system. Generally, there are two ways of blowing and suction. Dust-containing gas is driven into the return air duct by the air flow at the same level. The collected dust-containing gas is filtered by the high-efficiency purification equipment and then introduced into the air-supply duct by the fan to be sent into the room. Through continuous circulation, the air quality inside the plant is improved .

Introduction of suction arm

one

1.Suspended suction arm

The lifting suction arm and extension arm capture are suitable for fixed-point welding, welding of large and small parts, and local welding of large workpieces. The choice must be based on various factors such as the welding process, the size of the workpiece, and the operating habits of workers, without affecting the workers To achieve better capture results.

2.Lifting extension arm

A ceiling-mounted suction arm, standard arm or extension arm is installed at each welding station, and the suction arms are connected together through the main pipe, and finally integrated into the central smoke purification system, and all the smoke collected is purified by the central smoke The system performs centralized filtering, dust collection, and finally exhausts the atmosphere into clean air, which meets environmental protection standards.

3.Multi-suction arm dust extraction system

A ceiling-mounted suction arm, standard suction arm or extension arm is installed at each welding station, and the suction arms are connected together through the main pipe, and finally merged into the central smoke purification system, and all the smoke is sucked in the center The smoke and dust purification system performs centralized filtering, smoke and dust collection, and finally exhausts the atmosphere into clean air, which meets environmental protection standards.

Top smoking purification system

two

1.Top suction hood capture

For larger workpieces and more solder joints, the suction arm capture cannot meet the requirements. This requires the design of a top suction hood or a side suction hood with a large capture area to capture. Considering the characteristics of smoke and the requirements of the lifting process, The top suction hood can be designed as a fixed suction hood, a rotary fixed suction hood, a mobile top suction hood, and the like. The design for capturing the air volume is generally calculated according to the exhaust cross section of the top suction hood / plate: Q = S * V, V is 0.3 ~ 0.8m / s, and the determination of the side suction hood air volume needs to be multiplied by a factor of 1.5 ~ 3 (distance from the welding point) The position needs to be <1000mm). At the same time, in order to ensure the capture effect, a certain length of arc curtain can be hung around the top suction hood / board.

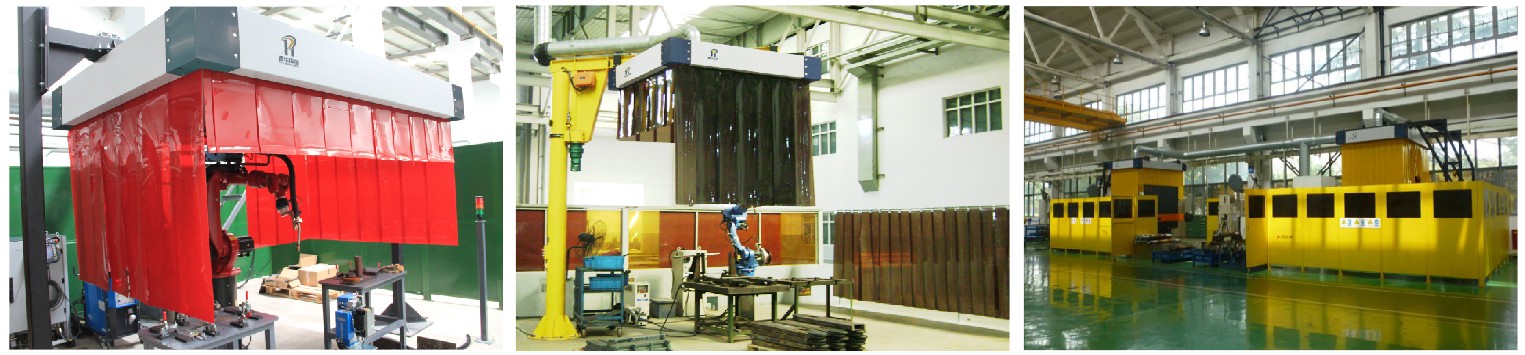

2.Protective curtain capture

For the robot welding conditions, because the workpiece is large and the robot has a wide range of motion, it is impossible to catch the generated smoke and dust at a fixed point. The countermeasure taken is that the generated smoke and dust limit is in a closed or semi-closed specific space. Ventilation is performed to ensure that the soot and dust generated will escape and affect the working environment of the workshop. The adopted method can be one-to-one separate dust extraction and purification, with the suction hood as the top of the workpiece, and at the same time hanging a curtain curtain of a certain length to effectively improve the collection of smoke and dust, to avoid the overflow of smoke and dust, or a multi-to-one central smoke Purification system.

3.Workplace capture

Workplace capture is to isolate the welding station from the external area. Welding production fume and dust are captured at the air outlet on the top of the workroom. Because the smoke and dust are confined to the workroom, under the effect of the suction of the air outlet, the workroom is in a Negative pressure to avoid the overflow of smoke and dust. The design of capturing air volume is generally calculated according to the ventilation interface of the workshop: Q = S * V, V is 0.1 ~ 0.3m / s. Its single station air volume is generally greater than 3000m3 / h.

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!