-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

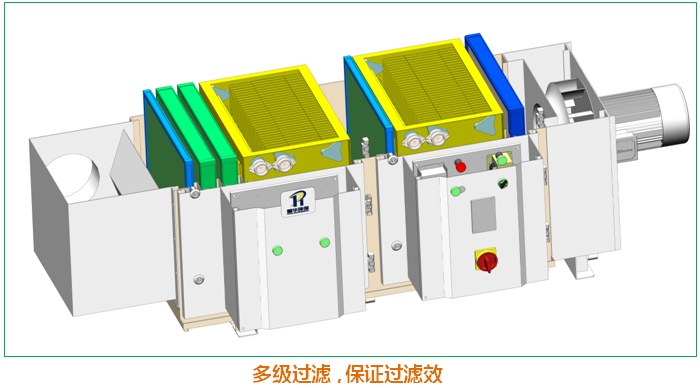

ZMED series is specially designed for large-scale CNC processing workshop, oil mist capture and purification of more than 10 stations. It adopts distributed capture, centralized filtering, central pipeline connection process, double electrostatic filtering, integrated body design, installation and maintenance. Convenient. It is especially suitable for multi-station oily cutting fluids in large workshops and continuous working occasions. It is widely used in CNC machine tools, cold heading machines, hobbing machines, engraving and

ZMED central two-stage oil mist purification system

ZMED series is specially designed for large-scale CNC processing workshop, oil mist capture and purification of more than 10 stations. It adopts distributed capture, centralized filtering, central pipeline connection process, double electrostatic filtering, integrated body design, installation and maintenance. Convenient. It is especially suitable for multi-station oily cutting fluids in large workshops and continuous working occasions. It is widely used in CNC machine tools, cold heading machines, hobbing machines, engraving and milling machines, precision blanking machines and other mechanical processing equipment that produces oil fume.

Product recommendation

fine

one

· Fundamental·

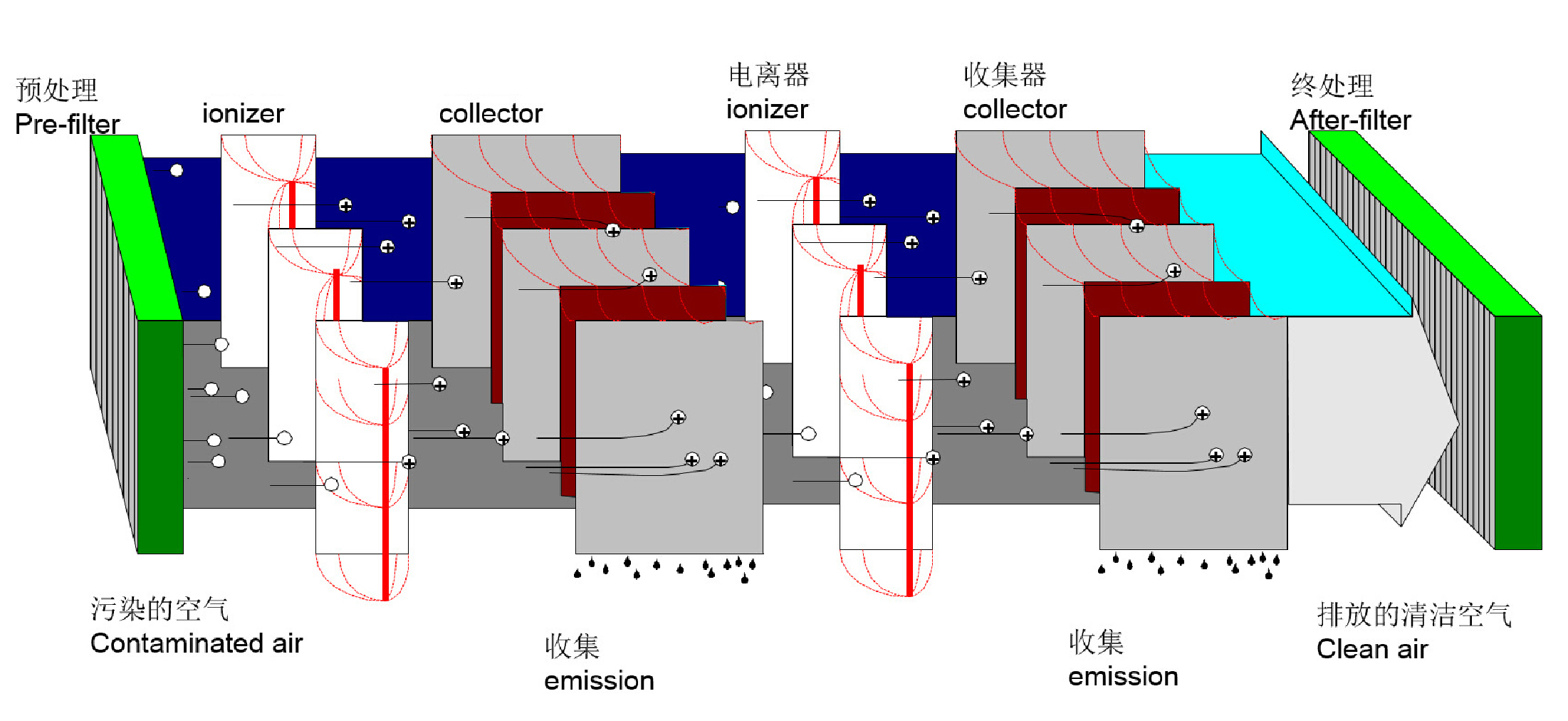

The electrostatic main filter unit is generally divided into an ionization section and a collection end. The ionization section uses the most advanced ultra-high voltage power supply (6kv ~ 12kv) in China to generate high-voltage static electricity. Under the action of a high-voltage plasma electric field, tiny oil particles and gas are ionized. Electricity and charged tiny ions (oil particles) enter the subsequent collection section with the wind. Due to the potential difference between the plates in the collection section, the positive and negative phase suction advection technology is used to adsorb the charged ions on the plates and gradually form them. The oil droplets are settled in the oil collecting tank, thereby realizing the degradation, purification, and discharge of oil mist particles and organic substances in the soot and oil mist exhaust gas.

two

· Features·

1.Power unit, stable and reliable

1.Power unit, stable and reliable

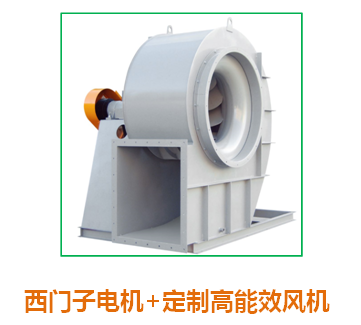

The fan power unit consists of a motor and a custom high-efficiency fan. The integrated compact design reduces the machine's floor space while ensuring negative air pressure.

ZMED series motors adopt Siemens brand, specially designed and customized high-efficiency centrifugal fans with excellent performance, low noise and good balance of movement.

———————————————————————————————————————————————— ————————————

2. High voltage power supply, high level protection

2. High voltage power supply, high level protection

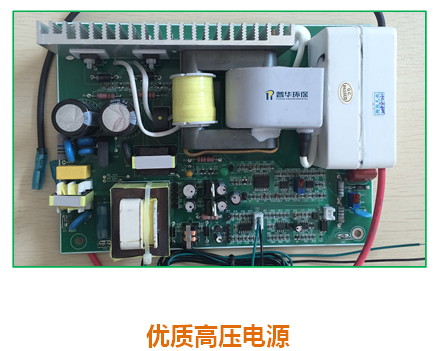

For high-voltage power supply, Puhua Environmental's own designed circuit control, double closed-loop control of current and voltage, and constant current and constant voltage output effectively prevent arcing and ensure constant purification efficiency

After 15 consecutive discharges, the power supply enters the protection state, that is, the output high voltage is 0 V, the 220 V power supply is disconnected, and the power is turned on after 20 seconds. The power supply restarts and enters the normal working state. This function is used to detect whether the user's load is too dirty to prompt the user to clean the load. This function allows the user to choose whether to use it.

———————————————————————————————————————————————— ————————————

3. Static filtration, low use and maintenance costs

3. Static filtration, low use and maintenance costs

The filtration system adopts a mechanical plate and frame filter + electrostatic field main filter combined structure:

In the first stage, a metal plate and frame filter is used, which plays a role of equalizing and intercepting large particles;

The second stage uses a multi-fiber metal filter to intercept small metal particles;

The third level uses a labyrinth metal filter to intercept large particles of oil mist;

The fourth level uses electrostatic filters, no consumables and low maintenance costs;

Fifth stage, metal filter, purification and current sharing;

Sixth stage, adopt electrostatic filter, second stage static, high efficiency filtering;

———————————————————————————————————————————————— ————————————

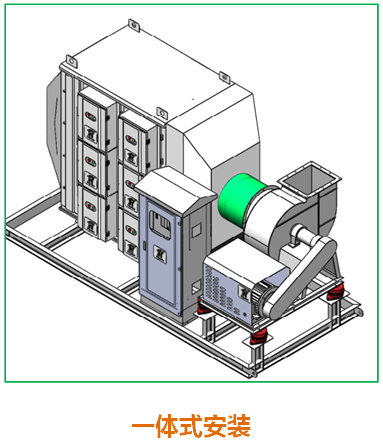

4. Integrated installation structure, convenient installation and maintenance

4. Integrated installation structure, convenient installation and maintenance

The mainframe installation method adopts an integrated structure, which integrates the filtering system, fan system and electronic control system on the same base. The entire system is assembled and debugged in the factory before shipment, and shipped to the construction site for overall hoisting and installation, which not only greatly reduces The period and difficulty of construction, and the connection and operation stability of the host system can be guaranteed.

———————————————————————————————————————————————— ————————————

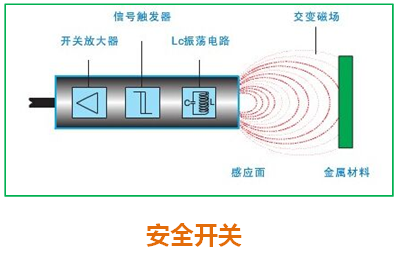

5, safety protection, anti-electric shock

5, safety protection, anti-electric shock

The safety protection is designed with a non-contact proximity switch. This equipment is equipped with a separate safety switch, that is, when the electric field door is opened, the machine automatically cuts off the power, which basically guarantees the safety of the operator and prevents the occurrence of high-voltage electric shock caused by misoperation.

———————————————————————————————————————————————— ————————————

6. Intelligent control, do what you want

6. Intelligent control, do what you want

As for the control system, the inverter is used for start-up and variable-frequency operation. The standard configuration is PLC and touch screen. The air volume of the oil mist purifier can be adjusted according to the number of CNC processing machine tools turned on to achieve the purpose of good ventilation effect and high filtering accuracy.

Electrical configuration remote and local control switching, main power switch, power indication, running indication, fault alarm indicator.

———————————————————————————————————————————————— ————————————

Three

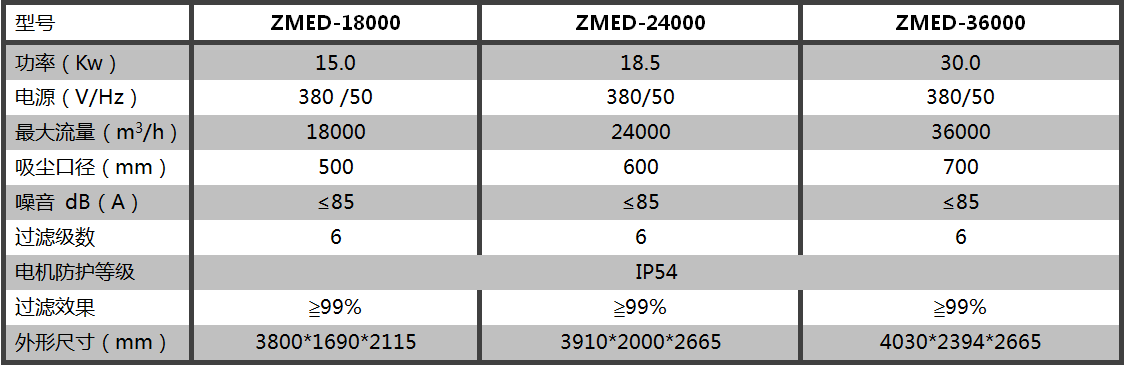

· Technical Parameters·

The ZMED central electrostatic oil mist purification system generally uses each pipeline to connect N processing machines in the workshop in parallel to the main pipeline. Due to the special nature of the oil mist, it is recommended to use PPS flame retardant ducts / seamless welded galvanized pipes / none Seam welded steel pipe / stainless steel pipe, etc. The welding and installation process guarantees no oil leakage.

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!