-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

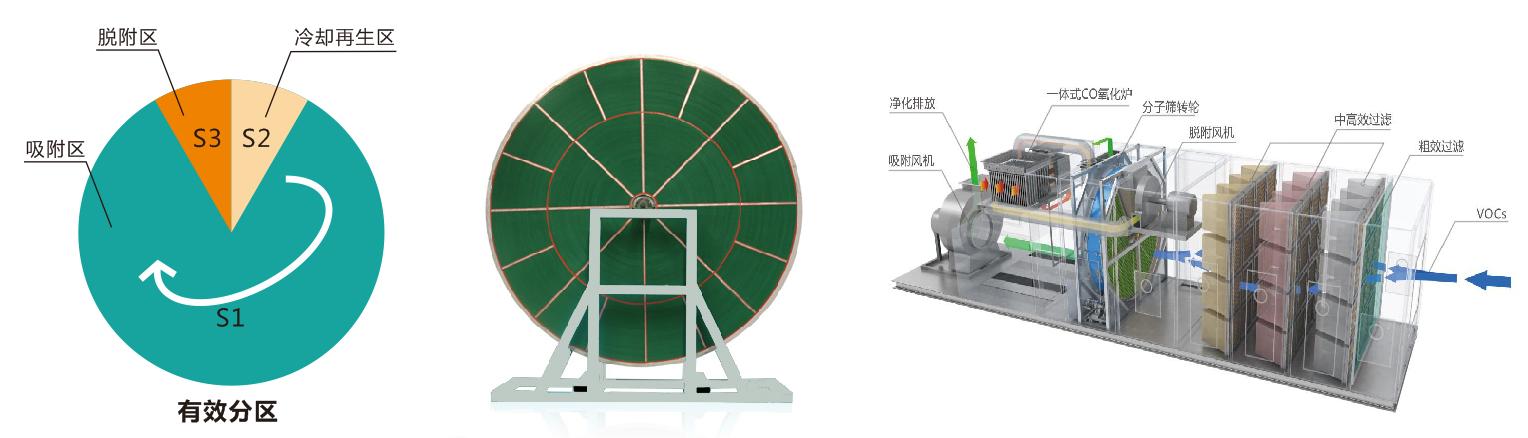

The zeolite wheel concentration adsorption uses three continuous temperature-changing adsorption and desorption devices of adsorption-concentration-desorption to condense organic waste gas with low concentration and large air volume into

concentrated gas with high concentration and small air volume . The desorbed and concentrated exhaust gas is sent to a catalytic combustion furnace for flameless combustion. Under the dual role of noble metal catalyst and electric heating, the exhaust gas is

Zeolite molecular sieve rotor adsorption concentration + catalytic combustion exhaust gas treatment system uses adsorption, desorption, and purification three continuous temperature-changing adsorption and desorption processes to concentrate low-concentration, high-volume organic waste gas into high-concentration, small-flow concentrated gas. High-concentration exhaust gas directly enters the catalytic combustion equipment for purification treatment. Its device characteristics are suitable for the treatment of high-flow, low-concentration, exhaust gas containing multiple organic components.

Product recommendation

fine

Product Principle

The sealing system of zeolite molecular sieve wheel adsorption is divided into adsorption region, desorption region and cooling region. The adsorption wheel rotates slowly to ensure that the entire adsorption is a continuous process. The exhaust gas containing volatile organic compounds (VOCs) passes through the adsorption of the wheel. In the area, the exhaust gas components therein are adsorbed by the adsorbent in the runner, the runner gradually becomes saturated, and the treated exhaust gas is purified and emptied. At the same time, in the desorption area, the high-temperature air passes through the adsorption-saturated runner, so that the exhaust gas that has been adsorbed in the runner is desorbed and taken away by the high-temperature air. A cooling zone is set between the desorption and the adsorption zone, thereby recovering The adsorption capacity of the runner achieves the effect of continuously removing VOCs, and also increases the concentration of exhaust gas, which is convenient for catalytic oxidation treatment. The high-temperature desorption hot air comes from the high-temperature flue gas generated in the catalytic combustion chamber. Before the desorbed concentrated exhaust gas enters the catalytic combustion bed, it first exchanges heat with the high-temperature flue gas in a heat exchanger unit to preheat the desorbed exhaust gas and enter the catalytic combustion bed. A heating device is arranged in the catalytic combustion bed to ensure that the desorbed gas rises to a specific temperature in the catalytic bed to perform a catalytic oxidation reaction, and the organic components are oxidized into non-toxic and harmless CO2 and H2O and emit heat. The formed high-temperature flue gas is heat-exchanged with the intake air during discharge, and is directly discharged into the chimney or divided to be used as desorption hot air. The continuous operation of the adsorption wheel rotating slowly can well adapt to continuous and intermittent operating conditions.

Features

1.Suitable for normal-temperature, low-concentration, high-volume organic waste gas purification operation is simple and convenient. The whole process of the system is automatically controlled by PLC, which can realize one-key startup and chain linkage control

2. Advanced equipment design principles, unique materials, stable performance, simple structure, safe and reliable, energy saving, no secondary pollution

3. The system is safe and reliable. It is equipped with multiple sets of temperature, pressure, gas sensors and alarm devices, and is equipped with safety protection measures such as fire arresters and explosion-proof membranes.

4, using modular structure, simple structure, modular form, fast production, simple installation, small equipment footprint, light weight. Adsorption bed adopts drawer structure, easy to load and easy to replace

5. Low power consumption. The catalytic combustion chamber uses a honeycomb ceramic-like noble metal catalyst with low resistance and high activity. Spontaneous combustion can be maintained when the concentration of organic waste gas exceeds 2000 PPm

6. The original high-volume, low-concentration VOCs exhaust gas is converted into low-air-volume, high-concentration exhaust gas, and the concentration factor is 5-20 times, which greatly reduces the specifications of the post-processing equipment and lowers the operating cost.

7. The zeolite concentration runner device has low pressure loss, high adsorption performance, low loss, low operating cost, excellent adsorption performance, large specific surface area, continuous and stable operation, and good desorption effect. Low energy consumption, high reliability, excellent design performance, and filtration efficiency ≥95%.

Scope and technical parameters

1. Suitable for low-concentration large-volume exhaust gas, especially for large-scale spray painting and baking room exhaust gas treatment.

2. It is suitable for various organic waste gas generating places such as organic waste gas in the chemical industry.

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!