-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

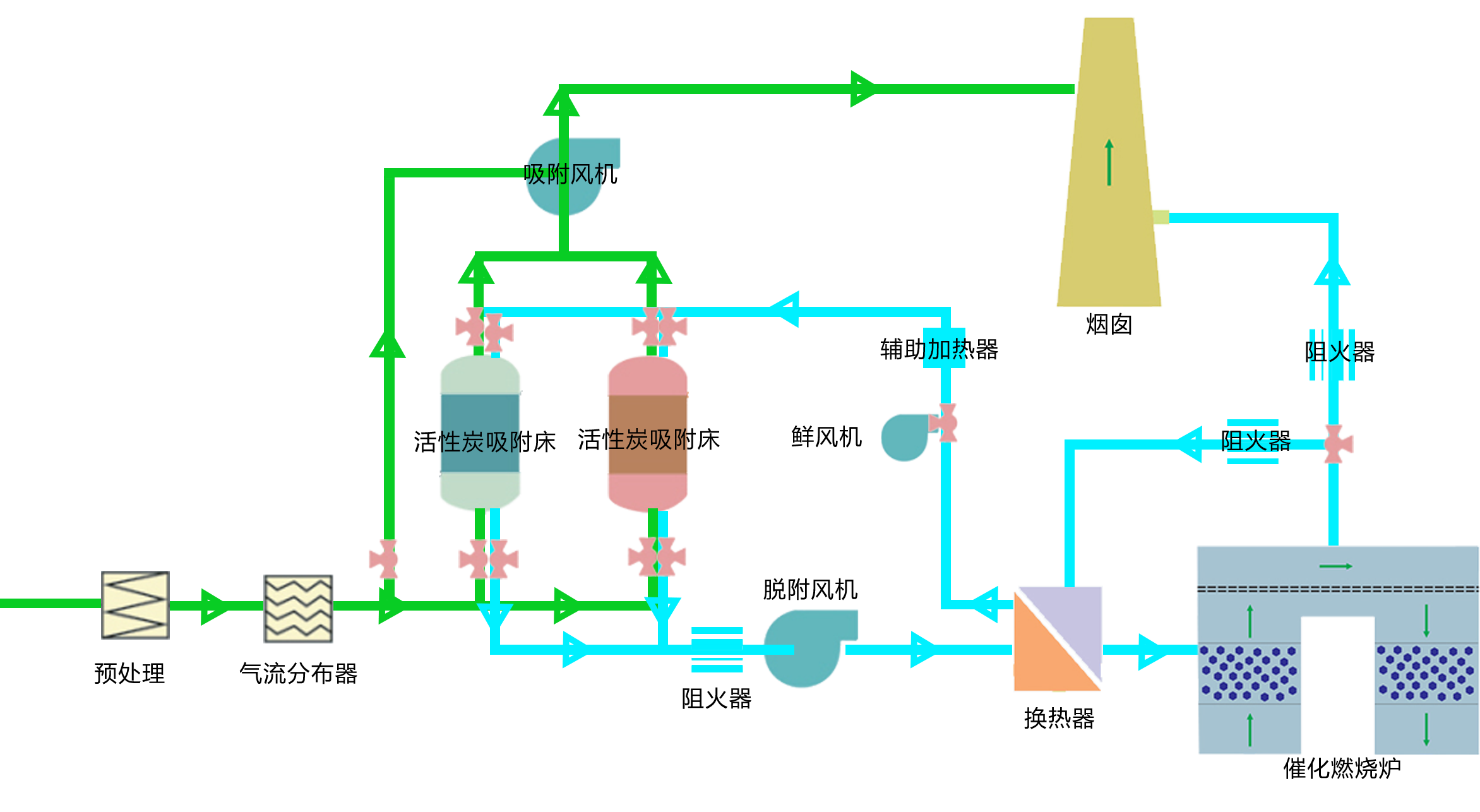

Activated carbon adsorption and desorption + catalytic combustion device is a VOCs treatment equipment independently developed by our company with years of experience in exhaust gas treatment. It is a method of organically combining an adsorption concentration unit and a thermal oxidation unit. It is mainly applicable to lower concentrations of organic gases and is not suitable. The organic waste gas treated by direct combustion and adsorption recovery can obtain satisfactory economic effects and treatment effects, especially

Activated carbon adsorption and desorption + catalytic combustion

Activated carbon adsorption and desorption + catalytic combustion device is a VOCs treatment equipment independently developed by our company with years of experience in exhaust gas treatment. It is a method of organically combining an adsorption concentration unit and a thermal oxidation unit. It is mainly applicable to lower concentrations of organic gases and is not suitable The organic waste gas treated by direct combustion and adsorption recovery can obtain satisfactory economic effects and treatment effects, especially for large air volume treatment occasions.

Product recommendation

fine

Three

· Product principle ·

Utilizing the characteristics of large specific surface area and large adsorption capacity of activated carbon, the adsorption treatment of low-concentration organic waste gas is an effective treatment method for heavy machinery, which can make the purification efficiency of organic waste gas up to 90% ~ 95%. However, the adsorption capacity of the adsorption material is limited, and the adsorption-saturated adsorption material needs to be recycled and reused to reduce operating costs. To this end, our company independently develops a complete set of mature and reliable activated carbon adsorption and desorption processes. After activated carbon adsorption is saturated, the activated carbon is restored with hot air desorption and regeneration to restore its ability to be used again. The concentration of organic exhaust gas can be concentrated by controlling the desorption gas flow More than 10-20 times, the desorbed exhaust gas passes into the catalytic combustion bed, and it ignites under the dual effects of electric heating and catalyst. The purification efficiency of the catalytic combustion process can reach more than 98%. After combustion, CO2 and H2O are generated and a lot of heat is released. This heat is recovered by heat exchange through a heat exchanger, and can be mixed with outdoor air to be used as activated carbon desorption gas, reducing energy consumption and no secondary pollution.

two

· Product Features ·

1. Adopting the combined process of adsorption and concentration + catalytic combustion, the entire system realizes a closed cycle of purification and desorption processes, no secondary pollution occurs during operation, and low equipment investment and operating costs

2. The equipment is equipped with PLC / human-machine interface + remote control system to realize remote intelligent control. The equipment operation and operation process are fully automated.

3. Specially shaped honeycomb block activated carbon is used as the adsorbent. The adsorbent has a long life, low adsorption system resistance and high purification efficiency.

4. Noble metal catalyst, high efficiency, high heat stability, long service life

5. The equipment has high purification efficiency, generally up to 98%

6. Safe and reliable, equipped with all-round protection measures such as fire arrester, vent, alarm indication and automatic shutdown.

7. The equipment adopts electric heating and flameless combustion, and the equipment runs safely.

8. Integrated, modular design and production, small footprint, fast installation, can be used for purification and treatment of organic waste gas produced by continuous or intermittent production

Three

· Scope of application ·

Spraying, painting, printing, plastics, electronic appliances, furniture and various chemical workshops for the purification and odor treatment of harmful organic waste gases that are volatilized or leaked. It is most suitable for low concentration and high air volume. Direct combustion or adsorption recovery is not suitable. Exhaust gas

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!