-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Dust removal for thermal furnace of lithium battery material

Lithium battery material sintering furnace production line powder leveling, vibration, sieving, unloading and dumping stations will generate dust, dust overflow will cause material loss, pollute the environment and damage some precision equipment, which requires excellent performance Dust collectors collect, filter and recycle dust

2.Dust removal by mixing and stirring battery materials

The vacuum planetary mixer mixes the positive and negative solid battery materials uniformly, then adds the solvent and stirs it into a slurry. The production line has dust escaping during loading, mixing, and stirring operations. Industrial dust collectors are required to capture the escaping dust and Filtration, indoor emission standards.

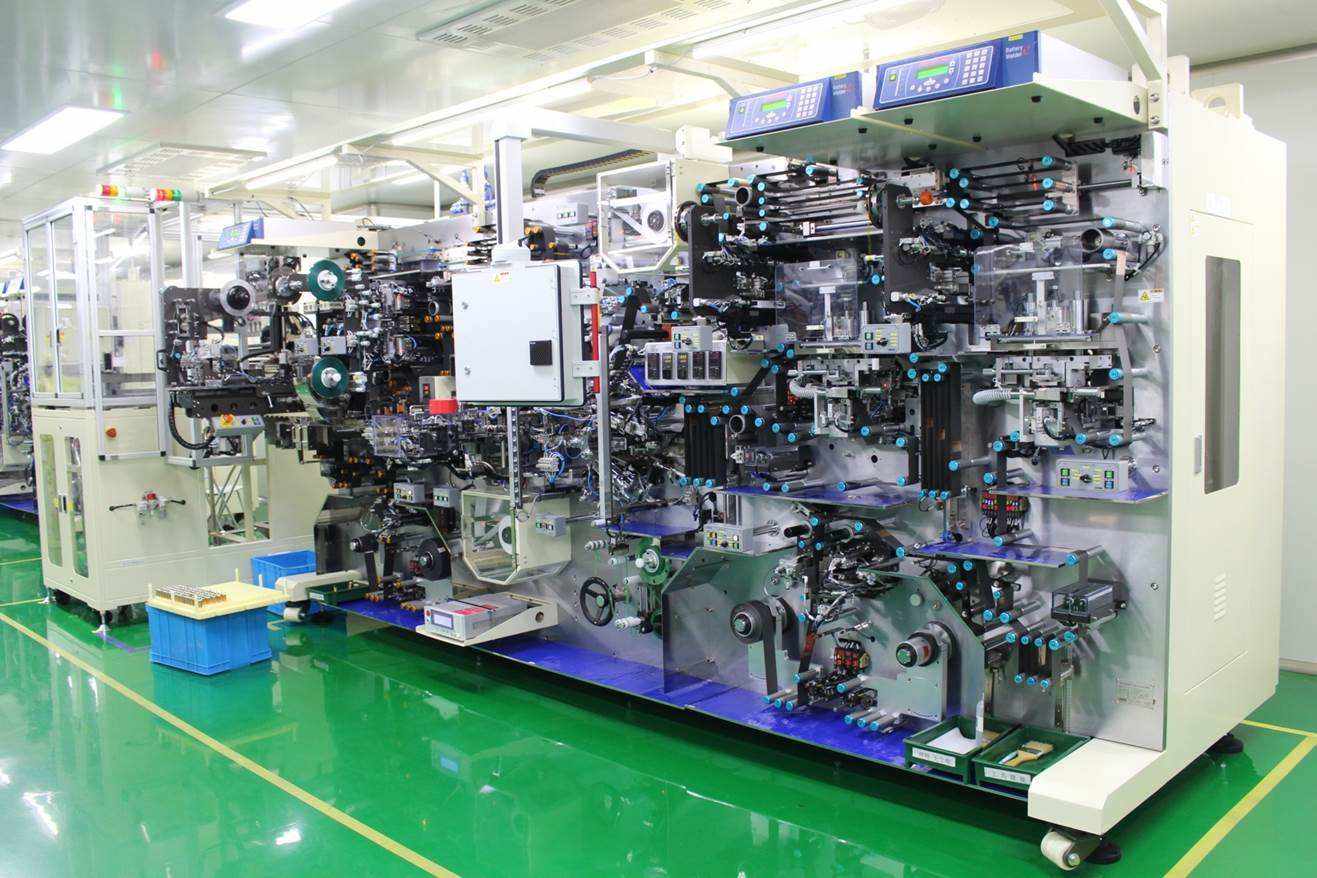

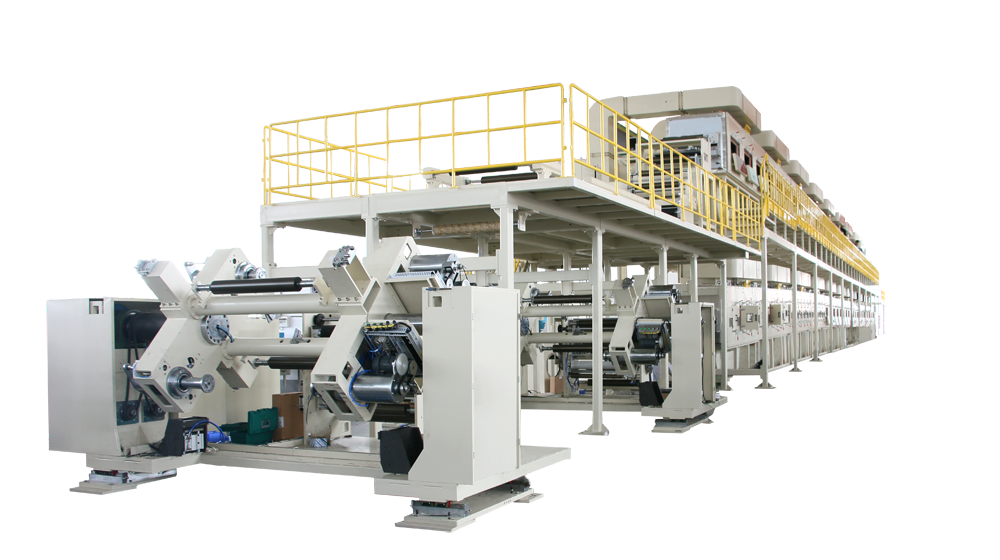

3.Pole strip slitting, film making, die cutting, dust removal for cell winding or lamination equipment

The full-automatic slitting machine continuously slits the wide entire roll of pole pieces into several narrow pieces of desired width. The cutting dust needs to be treated.

Fully automatic pole welding machine chip machine, laser pole forming machine welds the pole pieces after cutting, attaching protective tape, pole covering or using laser cutting to form the poles, etc. Subsequent winding process, welding and cutting fume need to be treated

Die-cutting is the die-cutting of gap-gap coating or continuous coating (single-side pole tab) after slitting, which is used for subsequent lamination process; roll-type die-cutting is continuous coating of rolls The pole pieces (with the ears on both sides) are completed with metal molds and then rolled up for subsequent slitting and winding processes. The dust and corner residues generated before and during die cutting need to be carried out. Collect and govern.

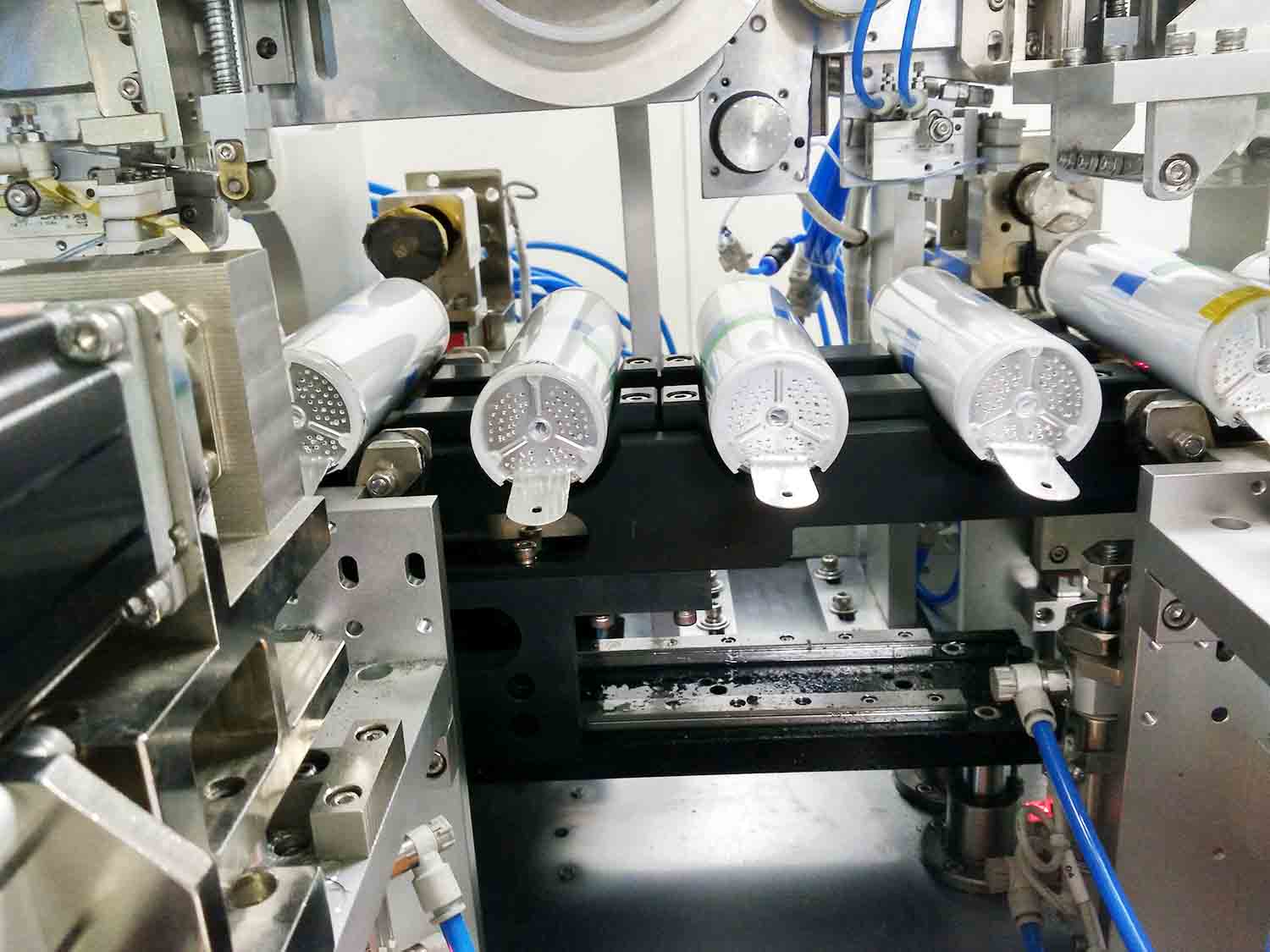

The cylindrical winding machine and the square winding machine wind the pole pieces produced in the film-making process or the roll-up die-cutting machine into the lithium ion battery cells, and control the dust adhered to the surface during the roll-up.

The full-automatic laminator is used to stack the individual pole pieces produced in the die-cutting process into lithium battery cells, and to control the surface dust during the lamination process.

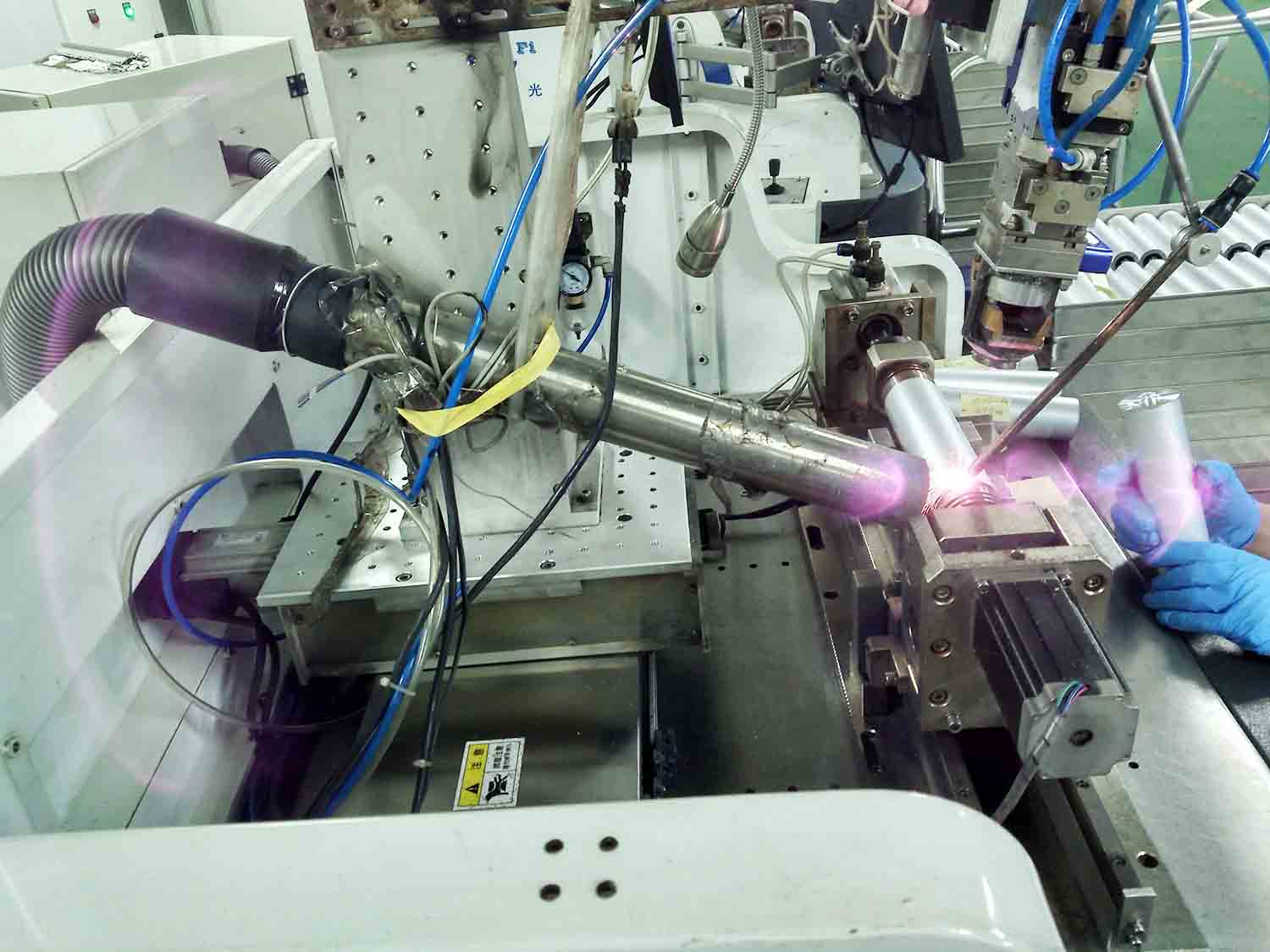

4.Dust control for laser welding, cleaning and marking operations of cell packaging

Lithium battery packaging shells will generate smoke and dust when welding, cleaning, and marking, which need to be handled in time, and the smoke has sparks, and it needs flame retardant design and treatment.

The outer packaging of lithium batteries is mostly made of aluminum alloy. Anti-static and fireproofing needs to be considered when dust is marked.