-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

ME series is specially designed for oil mist collection and purification of oily cutting fluid of CNC machine tools, electrostatic filtering, integrated body, low noise and low vibration. It is suitable for capturing and filtering of oily fumes in processing of various large, medium and small oily cutting fluids.

ME series electrostatic oil mist purifier

ME series is specially designed for oil mist collection and purification of oily cutting fluid of CNC machine tools, electrostatic filtering, integrated body, low noise and low vibration. Designed for oil mist treatment of industrial equipment, especially suitable for oily cutting fluid and continuous work place. Widely used CNC machining lathes, cold heading machines, hobbing machines, engraving and milling machines, fine blanking machines and other oil fume-producing mechanical processing equipment.

Product recommendation

fine

one

· Product principle ·

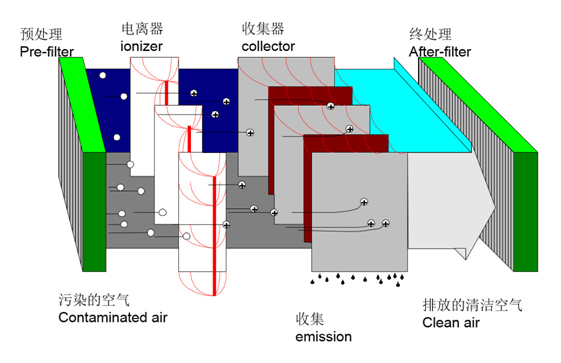

The electrostatic main filter unit is generally divided into an ionization section and a collection end. The ionization section uses the most advanced ultra-high voltage power supply (6kv ~ 12kv) in China to generate high-voltage static electricity. Under the action of a high-voltage plasma electric field, tiny oil particles and gas are ionized. Electricity and charged tiny ions (oil particles) enter the subsequent collection section with the wind. Due to the potential difference between the plates in the collection section, the positive and negative phase suction advection technology is used to adsorb the charged ions on the plates and gradually form them. The oil droplets are settled in the oil collecting tank, thereby realizing the degradation, purification, and discharge of oil mist particles and organic substances in the soot and oil mist exhaust gas.

The electrostatic main filter unit is generally divided into an ionization section and a collection end. The ionization section uses the most advanced ultra-high voltage power supply (6kv ~ 12kv) in China to generate high-voltage static electricity. Under the action of a high-voltage plasma electric field, tiny oil particles and gas are ionized. Electricity and charged tiny ions (oil particles) enter the subsequent collection section with the wind. Due to the potential difference between the plates in the collection section, the positive and negative phase suction advection technology is used to adsorb the charged ions on the plates and gradually form them. The oil droplets are settled in the oil collecting tank, thereby realizing the degradation, purification, and discharge of oil mist particles and organic substances in the soot and oil mist exhaust gas.

two

· Features·

1. Electrostatic filtration, no paper or fiber consumables, especially suitable for capturing and filtering oil mist of oily cutting fluid

2. High-efficiency EC fan or centrifugal fan (configured according to air volume requirements), efficient and stable performance, maintenance-free

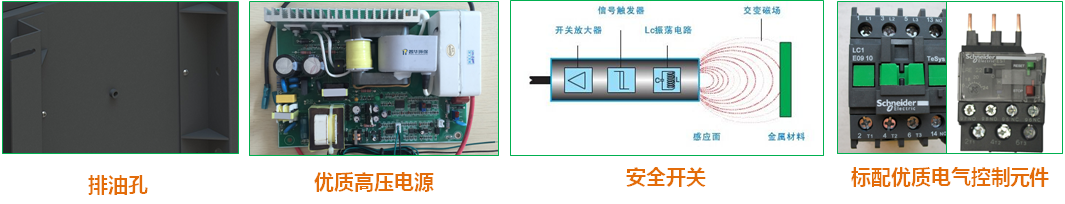

3. In terms of high-voltage power supply, Puhua's independent design of circuit control, double closed-loop control of current and voltage, and constant current and constant voltage output effectively prevent arcing and ensure constant purification efficiency.

4, with short circuit, over current, under voltage and overload protection; intelligent control arc (instantaneous or continuous arc) protection automatically cut off the high voltage output, and output a fault signal, can achieve remote control, completely solve the potential safety hazards

5. The safety protection design has a non-contact proximity switch. This device is equipped with a separate safety switch, that is, the panel of the electric field is turned on and the machine is automatically powered off, which basically guarantees the safety of the operator and other safety accidents.

6. The oil drainage system is designed with oil drainage holes, which can be controlled by manual ball valve, and can also be directly discharged into the equipment for recycling.

Three

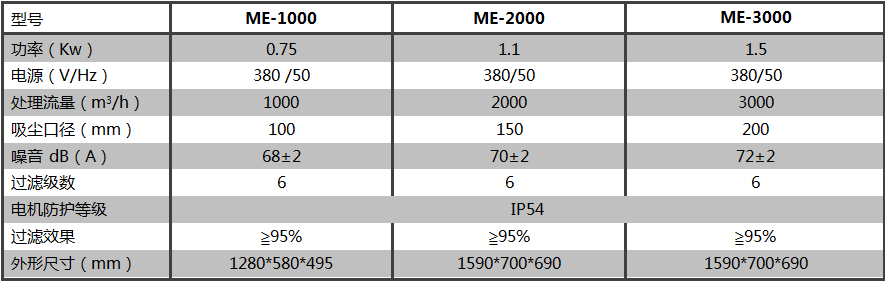

· Product parameters ·

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!