-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

MXV series oil mist purifier has a vertical structure and can be moved as its main feature. Suitable for a large number of oil mist places, specially designed for industrial equipment oil mist treatment, especially suitable for water-soluble cutting fluid, continuous work places. Widely used in machining industry, heat treatment industry, grinding machine, CNC machining lathe, etc.

MXV mechanical vertical oil mist purifier

MXV series oil mist purifier has a vertical structure and can be moved as its main feature. Suitable for a large number of oil mist places, specially designed for industrial equipment oil mist treatment, especially suitable for water-soluble cutting fluid, continuous work places. Widely used in machining industry, heat treatment industry, grinding machine, CNC machining lathe, etc.

Product recommendation

fine

one

· Product principle ·

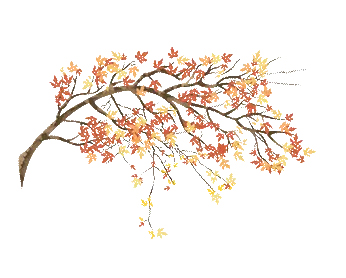

The oil mist first enters the equalizing chamber below the device, and large particles of oil mist stay in the equalizing chamber, and the fine oil droplets pass through the metal filter, labyrinth trap, medium-efficiency filter, and high-efficiency filter in order from bottom to top . Or activated carbon filters, etc., to achieve deep filtering effect.

The oil mist first enters the equalizing chamber below the device, and large particles of oil mist stay in the equalizing chamber, and the fine oil droplets pass through the metal filter, labyrinth trap, medium-efficiency filter, and high-efficiency filter in order from bottom to top . Or activated carbon filters, etc., to achieve deep filtering effect.

The top of the equipment is the fan and electrical control system, and finally clean air is exhausted from the top of the equipment. Specific operating conditions may be the exhaust duct connected to the central exhaust duct channels or external discharge.

two

· Features·

1. Vertical structure design, floor-standing structure, small footprint, easy operation.

2. Silent fan can be configured according to customers' requirements, which can reduce the equipment noise more effectively.

3. Filters that are configured according to the characteristics of different working conditions can maintain effective filtering and smooth gas for a longer time, and greatly reduce fan losses.

4. The modular structure of the filter is easy and quick to replace.

5, electrical design of the main power switch, thermal overload, phase sequence protection, running indicator.

6. The design of the separated oil storage chamber is reasonable and practical.

7, designed with oil drain holes, controlled by manual ball valve, can also be directly discharged into the equipment for recycling.

Three

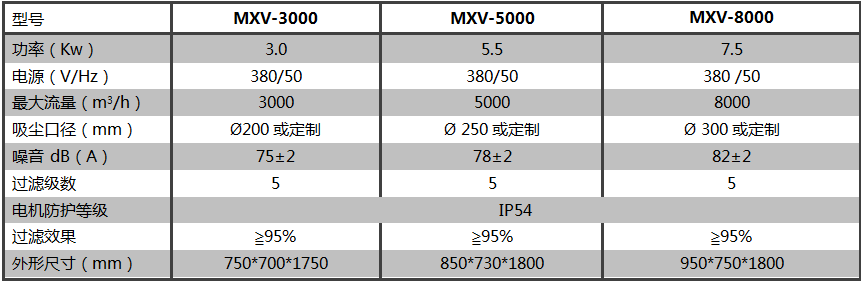

· Technical parameters and cases ·

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!