-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

Set grinding platform, filter, fan in one, equipped with pulse backflush, mobile industrial non-slip casters, easy to move.

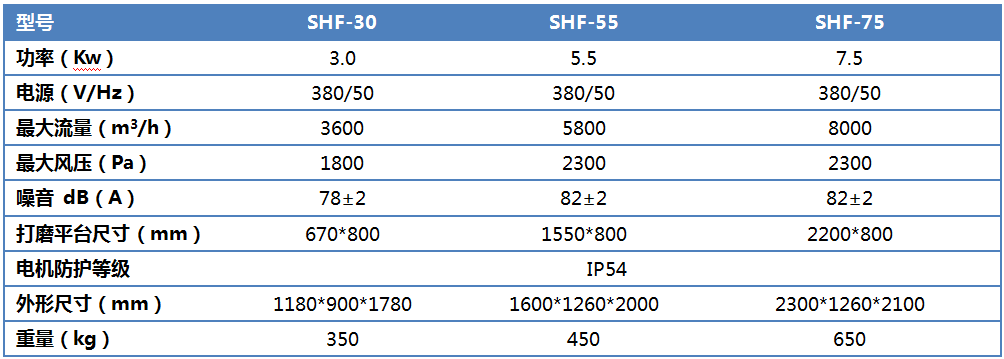

Power: 3.0kw-7.5kw 220V / 380V

Maximum flow rate: 8000 m3 / h

Maximum negative pressure: 2300mbar

Filter accuracy: 3um & 99.9%

Vibration dust method: Pulse dust cleaning

SHF / SHF-EX series pulse back blowing sanding table

Pulse back-brushing table features

one

1.Power unit, stable and reliable

1.Power unit, stable and reliable

The fan power unit is composed of a motor and a blade. The integrated compact design reduces the machine's floor space while ensuring negative air pressure.

Our SH-15 / SH-30 three-phase motors are Siemens branded, specially designed medium-pressure centrifugal impellers with excellent performance, low noise and good motion balance.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- -------

2.Filter cartridge filtration and quick release design

2.Filter cartridge filtration and quick release design

Filter cartridge type, polyester fiber material, high filtration accuracy, pleated design, large filtration area and small footprint.

The installation method of the filter cartridge adopts a quick-release structure design, which is very convenient for cleaning the filter cartridge. The filter cartridge can be taken out only by opening the end cover handle, which is convenient and practical.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- --------

3, cleaning system, efficient and reliable

Using the best filter cartridge cleaning technology so far, automatic pulse back-blow cleaning, and combined with the specially developed spiral injection technology, the cleaning area covers the entire surface of the filter cartridge, and there is no cleaning blind area.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- --------

4. Equipped with fluorescent lamp, with protective cover

4. Equipped with fluorescent lamp, with protective cover

The lighting system is humanized design of our company. SH-15 / SH-30 is equipped with a fluorescent lamp with a protective cover above the polishing table, which can be turned on when the light is relatively dark, which is convenient and convenient to use.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ---------

5. Configure the power socket of the grinder

5. Configure the power socket of the grinder

The power socket is a humanized design of our company. A 220V power socket is set on the side of the grinding table to facilitate the power-on operation of the grinding machine and avoid the use of additional wiring boards.

Typical application cases and parameters

two

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!