-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

The exhaust gas purification tower is also called the exhaust gas absorption tower. According to different purposes, it can be divided into acid and alkali washing towers, spray towers, swirl towers, packing towers, etc. According to different shapes, it can be divided into cylindrical and square. According to different materials, it can be divided into PP and PPS. , Carbon steel, stainless steel (201/304 / 316L), etc. It is widely used in the pretreatment of harmful exhaust gas and viscous gas. It can effectively separate the solids in the gas.

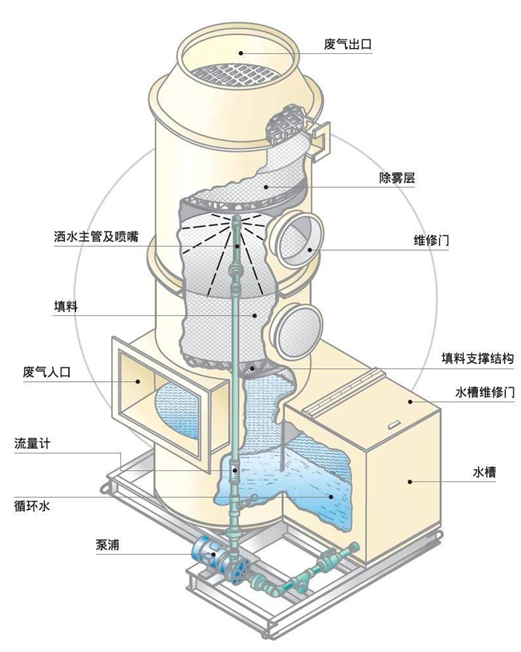

PP spray tower

The exhaust gas purification tower is also called the exhaust gas absorption tower. According to different purposes, it can be divided into acid and alkali washing towers, spray towers, swirl towers, packing towers, etc. According to different shapes, it can be divided into cylindrical and square. According to different materials, it can be divided into PP and PPS. , Carbon steel, stainless steel (201/304 / 316L), etc. It is widely used in the pretreatment of harmful exhaust gas and viscous gas. It can effectively separate the solids in the gas. At the same time, the spray tower is the main equipment for boiler flue gas using limestone wet desulfurization.

Product recommendation

fine

one

· Product principle ·

The packing layer in the tower serves as a mass transfer device for the contact members between the gas and liquid phases. The bottom of the spray tower exhaust gas purification device is equipped with a filler support plate, and the filler is placed on the support plate in an intricate manner. A pressure plate is installed above the packing to prevent it from being blown by the updraft. The spray liquid is sprayed onto the packing from the top of the tower through the liquid distributor and flows down along the surface of the packing. The gas is sent in from the bottom of the tower, and after being distributed by the gas distribution device, it passes through the gap of the packing layer in a countercurrent flow with the liquid. On the packing surface, the two phases of gas and liquid are in close contact for mass transfer. When the liquid flows down the packing layer, a wall flow phenomenon sometimes occurs, and the wall flow effect causes the gas and liquid phases to be unevenly distributed in the packing layer, thereby reducing the mass transfer efficiency. Therefore, the filler layer in the exhaust tower purification device of the spray tower is divided into two sections, and a redistribution device is arranged in the middle to spray on the lower filler after redistribution. In order to prevent the gas from carrying the spray liquid, a gas-water separator at the top of the tower effectively traps the spray liquid. The spray liquid is used cyclically, and there will be some losses during the use. The circulating water tank located at the bottom of the tower will replenish the spray liquid in a timely manner.

The packing layer in the tower serves as a mass transfer device for the contact members between the gas and liquid phases. The bottom of the spray tower exhaust gas purification device is equipped with a filler support plate, and the filler is placed on the support plate in an intricate manner. A pressure plate is installed above the packing to prevent it from being blown by the updraft. The spray liquid is sprayed onto the packing from the top of the tower through the liquid distributor and flows down along the surface of the packing. The gas is sent in from the bottom of the tower, and after being distributed by the gas distribution device, it passes through the gap of the packing layer in a countercurrent flow with the liquid. On the packing surface, the two phases of gas and liquid are in close contact for mass transfer. When the liquid flows down the packing layer, a wall flow phenomenon sometimes occurs, and the wall flow effect causes the gas and liquid phases to be unevenly distributed in the packing layer, thereby reducing the mass transfer efficiency. Therefore, the filler layer in the exhaust tower purification device of the spray tower is divided into two sections, and a redistribution device is arranged in the middle to spray on the lower filler after redistribution. In order to prevent the gas from carrying the spray liquid, a gas-water separator at the top of the tower effectively traps the spray liquid. The spray liquid is used cyclically, and there will be some losses during the use. The circulating water tank located at the bottom of the tower will replenish the spray liquid in a timely manner.

two

· Features·

1. Water-washing exhaust gas treatment system, with favorable price, simple treatment method, low operation and maintenance cost in the later stage

2.Vertical structure, small installation area, suitable for small spaces

3.Suitable for gaseous and liquid pollution sources

4. Conventional use is made of PP material and A board. It has beautiful appearance, smooth inside and outside, strong anti-corrosion, acid and alkali resistance, and anti-UV aging

5, with sparks or flammable and explosive dust or exhaust gas, it is recommended to use PPS flame retardant materials, self-extinguishing from the fire, to eliminate the hidden danger

6. For special purposes, it can be made of stainless steel, and the material can be selected from 201/304 / 316L, etc.

7. The equipment removal efficiency can reach more than 95%, and the performance is excellent

8, PP high-efficiency nozzle, large flow rate, 2 ~ 3 times higher than ordinary spiral nozzle

9.Special anti-corrosion water pump with excellent performance and long service life

10.Automatic water supply float valve, easy to maintain and clean

Three

· Scope of application

1. Treatment of various harmful gases such as H2S, SOX, NOX, HCI, NH3, CI2

2.Sewage treatment plant, waste landfill plant purification of exhaust gas

3.Semiconductor manufacturing industry, photoelectric industry, and other waste gas purification treatment

4. Treatment of exhaust gas from incinerators and industrial furnaces

5.Purification treatment of soot, acid, alkali, and malodorous gas discharged from printed circuit board industry, battery, electronic component industry, electroplating, pretreatment, chemical industry, steel industry, dyestuff industry, etc.

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!