-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

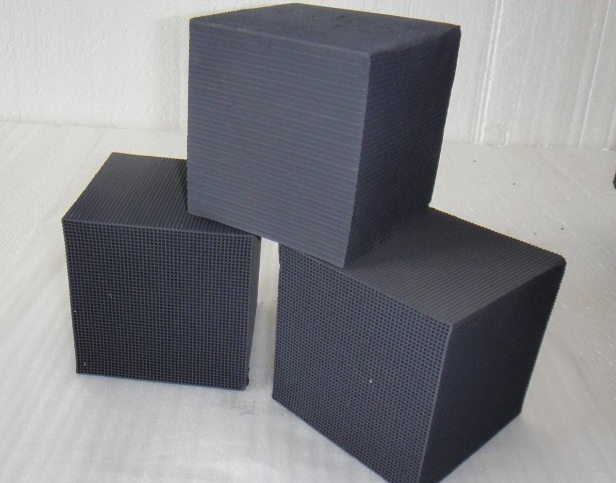

Activated carbon is a very small carbon particle with a large surface area, and there are more fine pores in the carbon particle-the capillary. This capillary has a strong adsorption capacity. Because the surface area of the carbon particle is large, it can It is in full contact with gas (impurities), and when these gases (impurities) hit the capillaries, they are adsorbed and play a purification role. The essence of activated carbon adsorption is to use the characteristics of activated carbon adsorption to adsorb organic solvents in low-

Activated carbon adsorption box

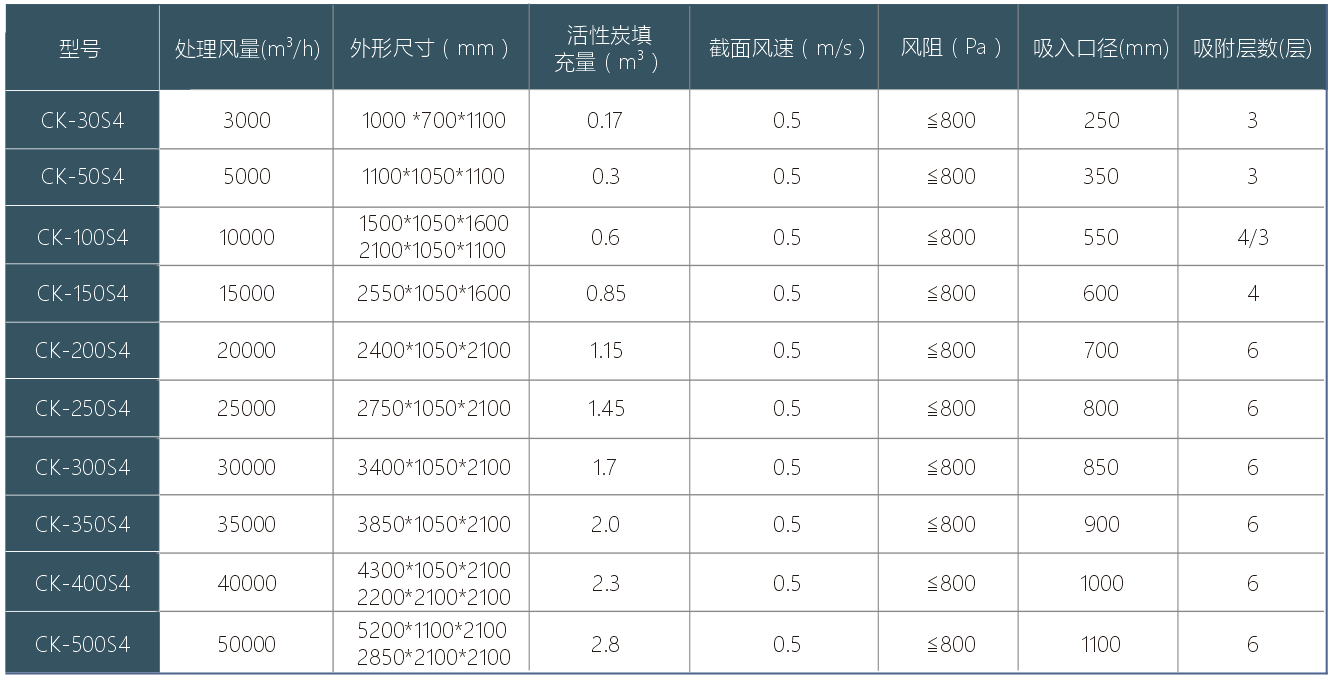

Our activated carbon equipment is specially designed for ammonia, hydrogen sulfide, carbon disulfide, methyl mercaptan, methyl sulfide, dimethyl disulfide, trimethylamine, styrene, and VOC organic waste gas. Different materials can be selected according to different waste gas components and concentration And different forms of activated carbon filter components, modular structure design, can be combined up, down, left and right to ensure that the requirements of air volume and filtration efficiency are met. Widely used in spray coating, food processing, printed circuit board, semiconductor manufacturing, chemical industry, electronics, leather industry, latex product industry, paper industry, etc., with high adsorption efficiency, strong capacity, compact structure, small footprint, convenient operation and maintenance, and cost Low, can handle a variety of exhaust gas at the same time, automatic operation, fully enclosed, both indoor and outdoor.

Product recommendation

fine

one

· Product principle ·

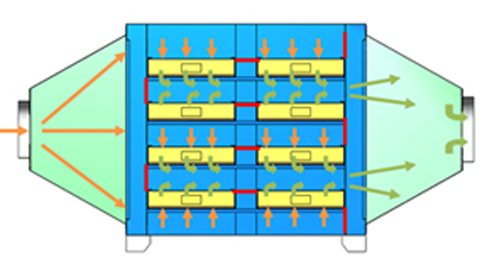

After the airflow enters the module through the air inlet, it first stays inside the funnel plate, which acts as a turbulent effect on the incoming gas, changes the direction of the airflow, and at the same time, the airflow speed becomes slower. It is divided into multiple strands of activated carbon passing through different cabinets, the odor is adsorbed by the activated carbon component, and the clean air is discharged through the exhaust port.

Adsorption process: Due to the presence of unbalanced and unsaturated molecular gravity or chemical bonding forces on the solid surface, when this solid surface is in contact with gas, it can attract gas molecules, make them condensed and remain on the solid surface. This phenomenon is called For adsorption. By utilizing the adsorption capacity of the solid surface, the exhaust gas is brought into contact with the porous solid substance on the large surface, and the pollutants in the exhaust gas are adsorbed on the solid surface to separate it from the gas mixture, thereby achieving the purpose of purification.

two

· Features·

1. All adopt drawer structure, simple and convenient replacement, modular design, can be replaced and filled at will

2.This technology can remove multi-component acid waste gas, alkaline waste gas, organic waste gas and odor at the same time

3.According to different exhaust gas components, different materials and different forms of activated carbon can be used to ensure the efficiency of adsorption.

4, conventionally made of carbon steel, electrostatic spraying on the surface, high-temperature baking, optional PP, 201, 316L, etc.

5.Can handle large air volume and low concentration of organic waste gas

6. Equipment technology is mature, less one-time investment, convenient installation and maintenance

Three

· Scope of application

1. Acid waste gas and acid mist, such as NO2, H2SO4, HCL, etc.

2. Alkaline exhaust gas, such as NH3, etc.

3. Organic waste gas and malodorous gases, such as benzenes, phenols, alcohols, tritium, etc.

4.Painting, spraying, ink printing, printing and dyeing workshop

5.Food, medicine, papermaking workshops

6.Treatment of exhaust gas from refineries, rubber plants, chemical plants, etc.

7.Post-processing device as UV photolysis and low temperature plasma processing equipment

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!