-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

For some exhaust gas with complex and oily exhaust gas, low-temperature plasma needs to be generated through corona discharge, creepage discharge, and dielectric barrier discharge, and through dielectric barrier discharge, glow discharge, corona discharge, and radiation discharge, etc. The temperature of the generated low-temperature plasma is as high as tens of thousands of degrees Celsius. When high-energy electrons collide with VOCs molecules, these volatile organic compound molecules are directly

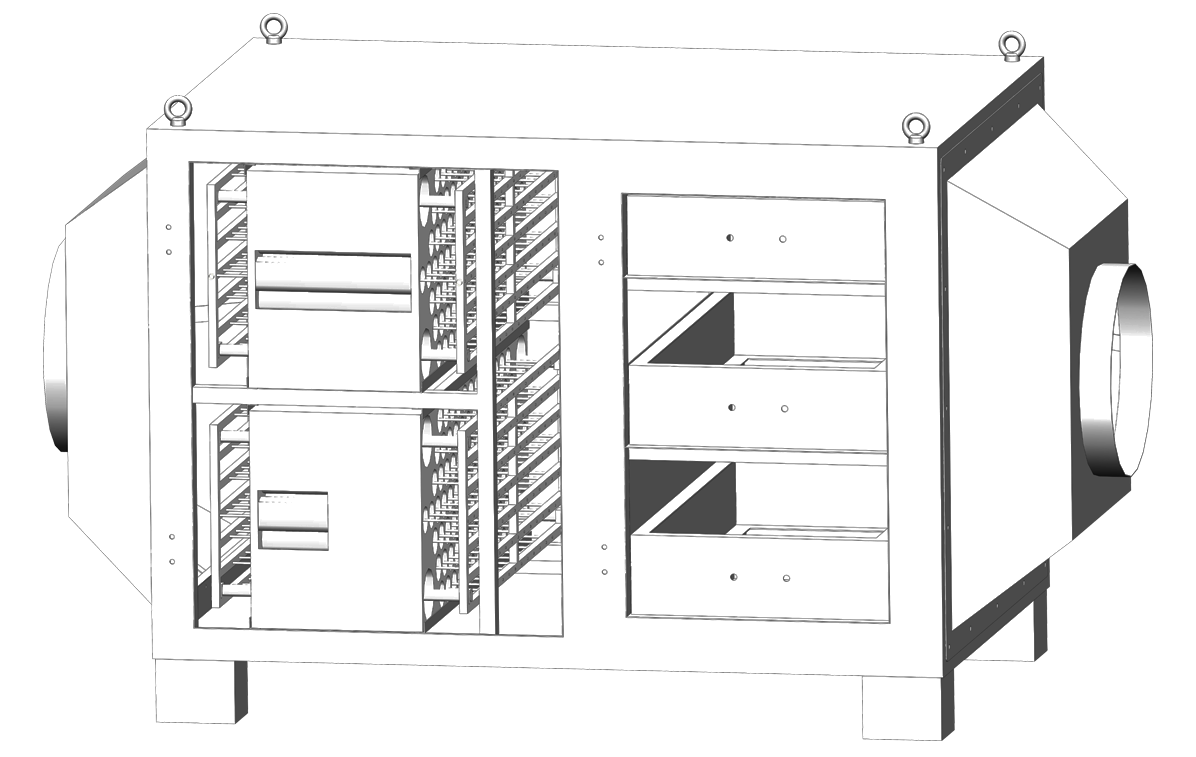

Plasma activated carbon machine

For some exhaust gas with complex and oily exhaust gas, low-temperature plasma needs to be generated through corona discharge, creepage discharge, and dielectric barrier discharge, and through dielectric barrier discharge, glow discharge, corona discharge, and radiation discharge, etc. The temperature of the generated low-temperature plasma is as high as tens of thousands of degrees Celsius. When high-energy electrons collide with VOCs molecules, these volatile organic compound molecules are directly bombarded and degraded, accompanied by excitation, ionization, Dissociation and other reactions occur. These VOCs macromolecules are converted into non-toxic and harmless molecules such as H2O and C, which are then efficiently adsorbed by activated carbon to achieve emissions.

Product recommendation

fine

one

· Product principle ·

Under the action of an external electric field, a large number of high-energy electrons produced by the dielectric discharge bombard the pollutant molecules, causing them to ionize, dissociate and excite, and then trigger a series of complex physical and chemical reactions to make complex macromolecular pollutants simple. Small-molecule safe substances, or turn toxic and harmful substances into non-toxic and harmless or low-toxic and low-hazard substances, so that pollutants can be degraded and removed. Because the average energy of the electrons generated after ionization is between 1eV and 10eV, proper control of the reaction conditions can achieve chemical reactions that are difficult to achieve or slow in general, and become very fast. After passing through the activated carbon adsorption box, the developed pore structure and large specific surface area of the activated carbon are used to capture and adsorb the residual exhaust gas, and finally achieve the standard discharge.

Under the action of an external electric field, a large number of high-energy electrons produced by the dielectric discharge bombard the pollutant molecules, causing them to ionize, dissociate and excite, and then trigger a series of complex physical and chemical reactions to make complex macromolecular pollutants simple. Small-molecule safe substances, or turn toxic and harmful substances into non-toxic and harmless or low-toxic and low-hazard substances, so that pollutants can be degraded and removed. Because the average energy of the electrons generated after ionization is between 1eV and 10eV, proper control of the reaction conditions can achieve chemical reactions that are difficult to achieve or slow in general, and become very fast. After passing through the activated carbon adsorption box, the developed pore structure and large specific surface area of the activated carbon are used to capture and adsorb the residual exhaust gas, and finally achieve the standard discharge.

two

· Features·

1. Modular integrated equipment, working under normal temperature and pressure, easy to operate.

2. The low temperature plasma technology is suitable for the removal of low and medium concentrations of VOCs, which requires very low energy consumption during work, and is used with non-energy activated carbon.

3. It is generally made of 304 stainless steel, and the material can be carbon steel, 201, 316L, etc.

4, high purification efficiency, the final product is H2O, CO and CO2, combined with multi-stage combined treatment of activated carbon, to avoid post-processing problems in other ways. excellent

5. Fire-resistant performance, adopts the triple automatic protection function design of switch, power supply and circuit. The equipment has exquisite appearance, exquisite volume, and convenient installation and maintenance.

Three

· Scope of application

1. Treatment of various harmful gases such as H2S, SOX, NOX, NH3, trimethylamine, methyl sulfide, methyl mercaptan, methyl sulfide, benzene, toluene, xylene, styrene and other odorous gases

2.Painting, spraying, ink printing, printing and dyeing workshop

3.Food, medicine, papermaking workshop

4.Treatment of exhaust gas from refineries, rubber plants, chemical plants, etc.

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!