-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

Low-temperature plasmas can generally be generated by corona discharge, creeping discharge, and dielectric barrier discharge. Low-temperature plasmas generated by dielectric barrier discharge, glow discharge, corona discharge, and arc discharge. The temperature of electrons in the system is as high as At 10,000 degrees Celsius, when high-energy electrons collide with VOCs molecules, these volatile organic compound molecules will be directly bombarded and degraded. With the occurrence of reactions such as excitation,

Low-temperature plasma waste gas treatment equipment

Low-temperature plasmas can generally be generated by corona discharge, creeping discharge, and dielectric barrier discharge. Low-temperature plasmas generated by dielectric barrier discharge, glow discharge, corona discharge, and arc discharge. The temperature of electrons in the system is as high as At 10,000 degrees Celsius, when high-energy electrons collide with VOCs molecules, these volatile organic compound molecules will be directly bombarded and degraded. With the occurrence of reactions such as excitation, ionization, and dissociation, these VOCs macromolecules are converted into Non-toxic and harmless molecules such as H2O and CO2, thus achieving purification effect.

Product recommendation

fine

one

· Product principle ·

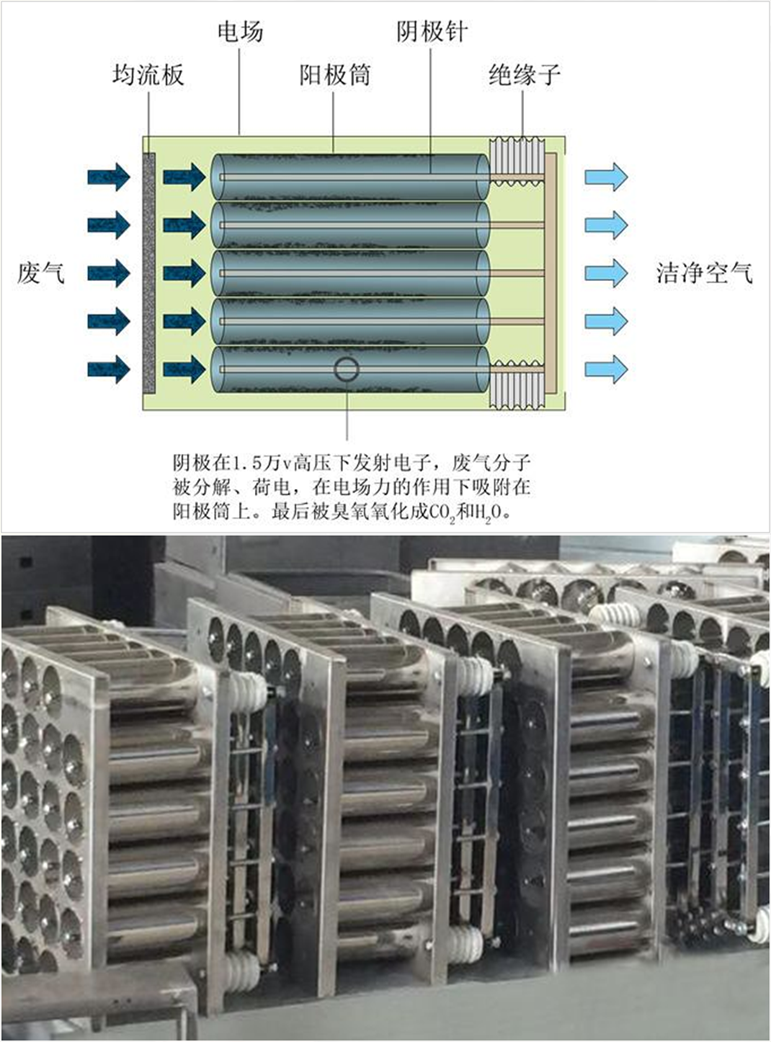

Under the action of an external electric field, the electrons obtain energy from the electric field and become high-energy electrons. These high-energy electrons are very fast. When they contact the pollutants, they transfer their own energy to the pollutants through inelastic collisions and turn them into pollution. The internal energy or kinetic energy of biomolecules. These energy-getting molecules are excited or ionized to form active groups. On the one hand, these active genes react with pollutant molecules to finally produce CO2 and H2O. On the other hand, when the pollutant molecules obtain When its energy is greater than its own binding bond energy, the molecular bonds of the pollutant molecules are broken and decomposed into harmless gases or elemental atoms. The plasma contains a large number of high-energy electrons, positive and negative ions, and excited particles. After the oxygen and water in the air are ionized, they become oxygen atoms and hydrogen atoms. When the oxygen atoms combine with oxygen and other single atoms, a large amount of OH and H2O are generated. Active free radicals such as O and O and highly oxidizing O3, these radicals undergo a series of complex chemical reactions with harmful gas molecules, and finally produce harmless or low-hazard products.

Under the action of an external electric field, the electrons obtain energy from the electric field and become high-energy electrons. These high-energy electrons are very fast. When they contact the pollutants, they transfer their own energy to the pollutants through inelastic collisions and turn them into pollution. The internal energy or kinetic energy of biomolecules. These energy-getting molecules are excited or ionized to form active groups. On the one hand, these active genes react with pollutant molecules to finally produce CO2 and H2O. On the other hand, when the pollutant molecules obtain When its energy is greater than its own binding bond energy, the molecular bonds of the pollutant molecules are broken and decomposed into harmless gases or elemental atoms. The plasma contains a large number of high-energy electrons, positive and negative ions, and excited particles. After the oxygen and water in the air are ionized, they become oxygen atoms and hydrogen atoms. When the oxygen atoms combine with oxygen and other single atoms, a large amount of OH and H2O are generated. Active free radicals such as O and O and highly oxidizing O3, these radicals undergo a series of complex chemical reactions with harmful gas molecules, and finally produce harmless or low-hazard products.

The physical effect is manifested in that the plates have the function of charging and collecting dust. A large number of electrons and particles in the plasma collide with the surface inelastically and adhere to the surface to charge them. Under the action of an external electric field, the charged particles move to the dust collector and are collected by the dust collector. The biological effect is manifested in the effect of sterilization. The positive and negative particles in the plasma cause the shear force of the electrical energy generated by the surface of the microorganism to be greater than the surface tension of the cell membrane, resulting in the destruction of the cell membrane and the death of the microorganism.

two

· Features·

1. Plasma equipment basically works at normal temperature and pressure, and is easy to operate. This technology can remove multi-component VOCs at the same time.

2. Plasma technology is suitable for the removal of low and medium concentrations of VOCs. It requires a higher voltage during operation, but the energy consumption is very low.

3. It is conventionally made of 304 stainless steel, and the material can be selected from carbon steel, 201, 316L, etc.

4. High purification efficiency. The final products are H2O, CO, and CO2. When the organics are chlorinated, chlorides should be added without other intermediate by-products, which reduces the toxicity of organics and avoids the post-processing problems in other ways

5. Excellent fire protection performance, adopting triple automatic protection function design of switch, power supply and circuit

6. Small size, compact structure, modular structure, convenient installation and maintenance

Three

· Scope of application

1. Various harmful gases such as H2S, SOX, NOX, NH3, trimethylamine, methyl sulfide, methyl mercaptan, methyl sulfide, dimethyl disulfide, carbon disulfide, benzene, toluene, xylene, styrene deal with

2.Painting, spraying, ink printing, printing and dyeing workshop

3.Food, medicine, papermaking workshop

4.Treatment of exhaust gas from refineries, rubber plants, chemical plants, etc.

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!