-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

UV photolysis is one of the methods for photocatalytic waste gas treatment. Photocatalytic method uses photoexcitation to separate the electrons and holes of the catalyst for oxidation and reduction of pollutants adsorbed on it.

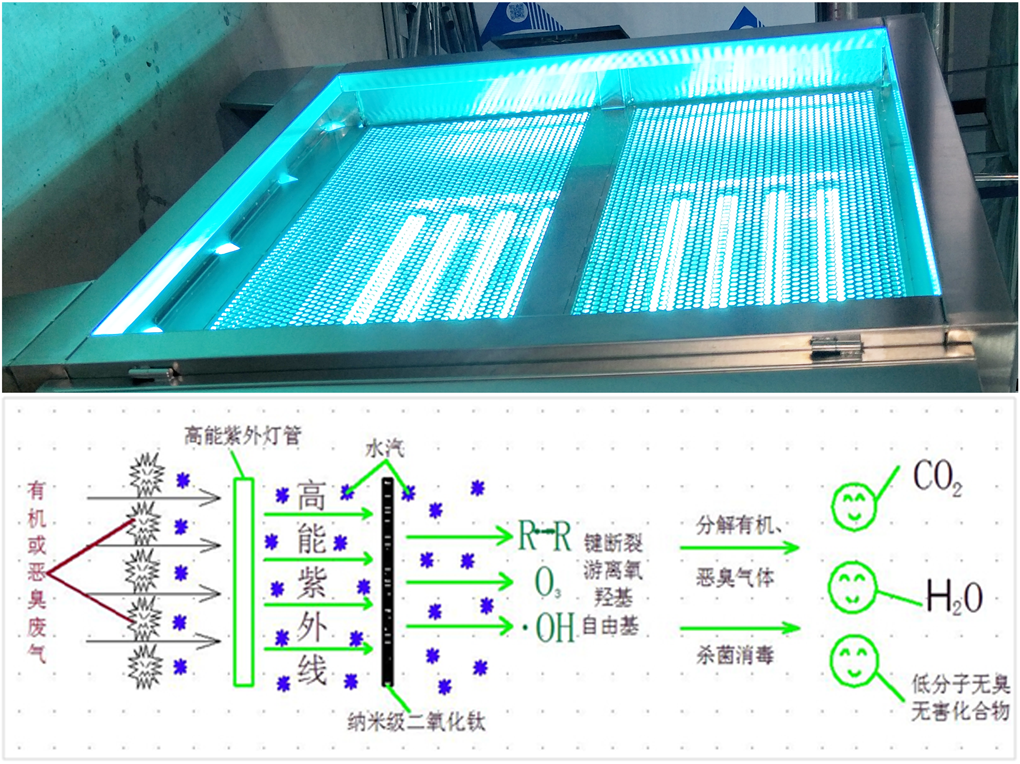

UV photolysis waste gas treatment equipment

UV photolysis is one of the methods for photocatalytic waste gas treatment. Photocatalytic method uses photoexcitation to separate the electrons and holes of the catalyst for oxidation and reduction of pollutants adsorbed on it. A large number of studies and customer cases prove that UV light catalysis has a good degradation effect on benzene, toluene, styrene, formaldehyde, acetaldehyde, ethylene, n-hexane, ammonia, hydrogen sulfide, mercaptans, etc. It has high reaction efficiency, easy recovery, small device footprint, and simple operation, and is particularly suitable for low-concentration exhaust gas treatment.

Product recommendation

fine

one

· Product principle ·

The high-voltage power source excites the UV light to emit light, and generates a high-energy UV light beam. The ultraviolet light in a specific band (253.7nm) decomposes the molecular chain of the malodorous gas, breaking its large molecular structure into a small molecular structure. Ultraviolet light in a specific band (185nm) of the ultraviolet light beam causes oxygen molecules in the air to generate free oxygen, that is, active oxygen. Due to the imbalance of the positive and negative electrons carried by free oxygen, it must be combined with oxygen molecules to generate ozone. Ozone has extremely strong oxidizing properties, and has a strong elimination effect on malodorous gases. Finally, through the superposition of multiple effects, the malodorous gas molecules are oxidized into inorganic substances such as CO2 and H2O.

two

· Features·

1.Modular structure, simple installation and maintenance, small footprint, convenient operation

2. Low use cost, except for the equipment itself, there is no need to add any additional substances to participate in the chemical reaction.

3. It is conventionally made of 304 stainless steel, and the material can be selected from carbon steel, 201, 316L, etc.

4. Efficient deodorization. Titanium dioxide is a non-dissolvable material.It completely decomposes organic matter and sterilizes it.

5. The photocatalytic reaction is generally carried out at normal temperature, and rarely causes secondary pollution, which is widely used.

6. Under normal maintenance, the service life of high-energy UV lamps is generally more than 3 years, and the equipment design service life is more than 10 years.

Three

· Scope of application

1, various harmful gases such as NH3, H2S, SOX, NOX, trimethylamine, methyl sulfide, methyl mercaptan, methyl sulfide, dimethyl disulfide, carbon disulfide, benzene, toluene, xylene, styrene and other malodorous gases deal with

2.Sewage treatment plant, waste landfill plant purification of exhaust gas

3.Semiconductor manufacturing industry, photoelectric industry, and other waste gas purification treatment

4.Treatment of exhaust gas from refineries, rubber plants, chemical plants, etc.

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!