-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

For some exhaust gas components that are more complex, high ozone-type ultraviolet beams, oxidation reaction catalysts, activated carbon and other processes are required to degrade organic exhaust gas with complex components, such as: ammonia, trimethylamine, hydrogen sulfide, methyl mercaptan, methyl mercaptan, methyl sulfur Ether, dimethyl disulfide, carbon disulfide, styrene, toluene, benzene, xylene, etc., change their molecular chain structure, so that the molecular chains of organic or inorganic high-molecular odor

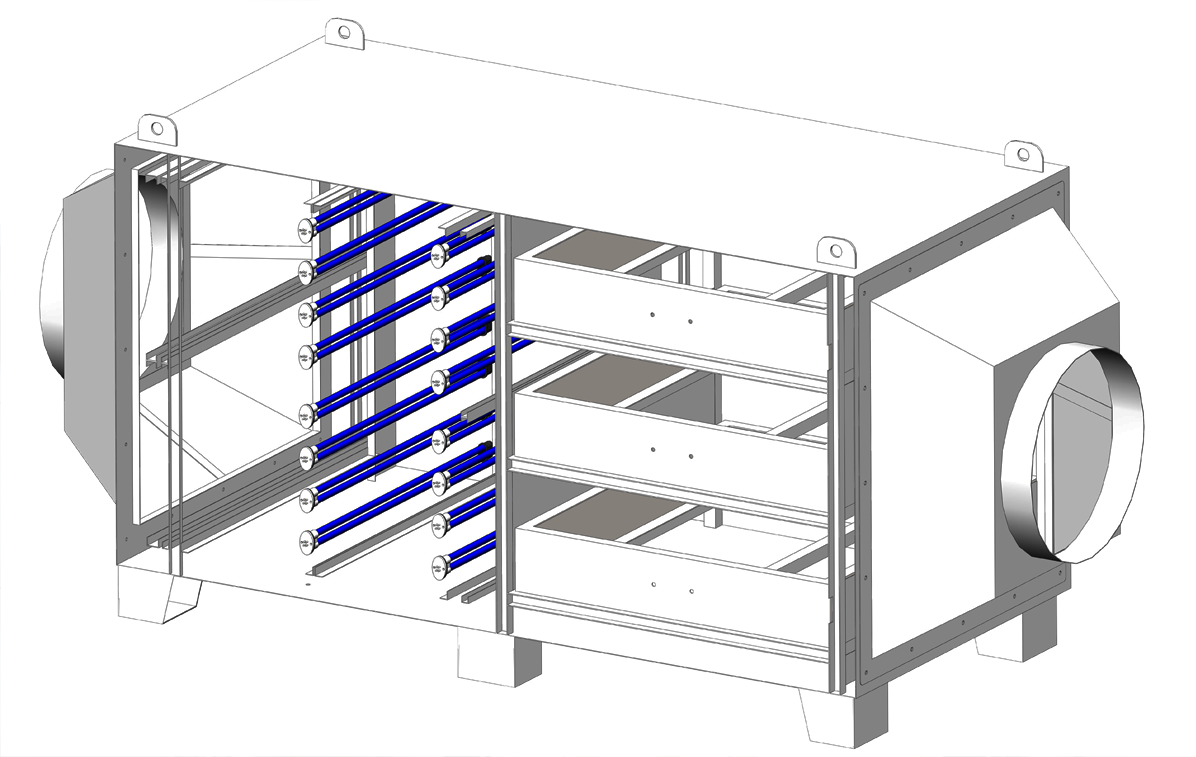

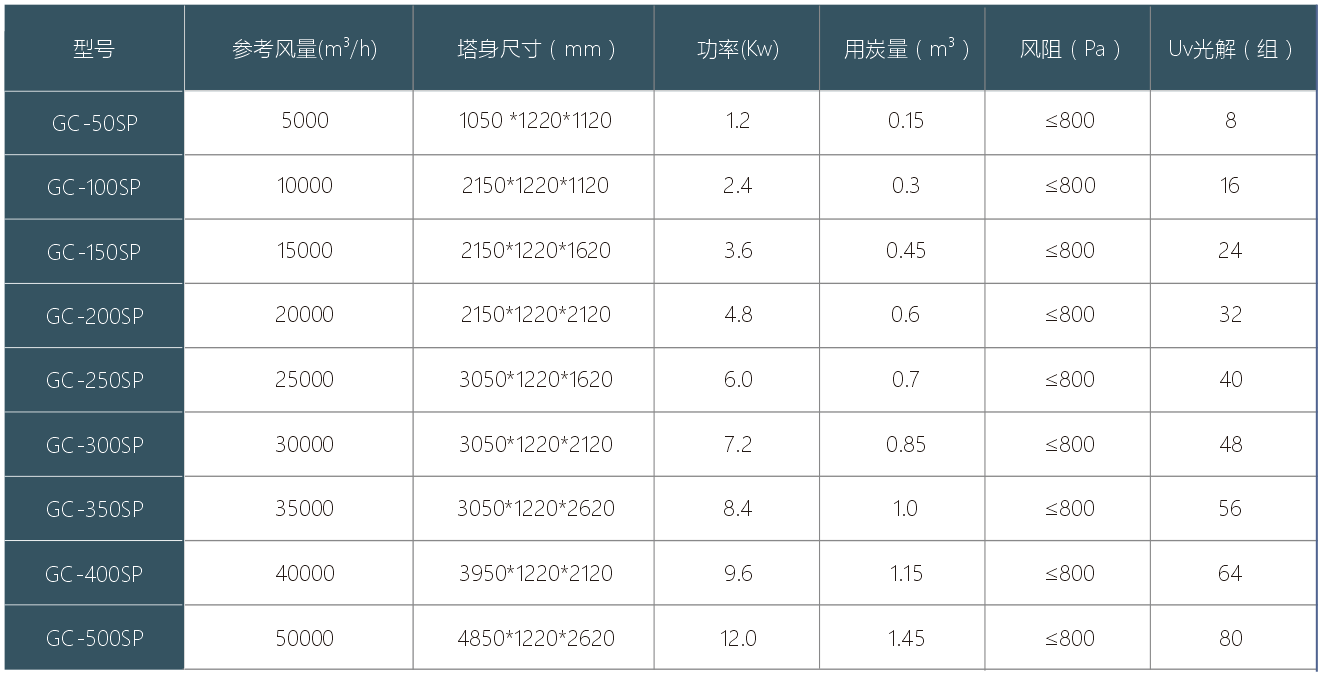

UV photolytic activated carbon machine

For some exhaust gas components that are more complex, high ozone-type ultraviolet beams, oxidation reaction catalysts, activated carbon and other processes are required to degrade organic exhaust gas with complex components, such as: ammonia, trimethylamine, hydrogen sulfide, methyl mercaptan, methyl mercaptan, methyl sulfur Ether, dimethyl disulfide, carbon disulfide, styrene, toluene, benzene, xylene, etc., change their molecular chain structure, so that the molecular chains of organic or inorganic high-molecular odor compounds are irradiated with high-energy ultraviolet beams, catalysts, and positive ion ions. Oxidation reaction, degradation to low-molecular compounds, such as CO2 and H2O, etc., and then through the efficient adsorption of activated carbon, so as to meet the standard emissions.

Product recommendation

fine

one

· Product principle ·

The high-voltage power source excites the UV light to emit light, and generates a high-energy UV light beam. The ultraviolet light in a specific band (253.7nm) decomposes the molecular chain of the malodorous gas, breaking its large molecular structure into a small molecular structure. Ultraviolet rays in a specific band (185nm) cause oxygen molecules in the air to generate free oxygen, that is, active oxygen. Because the positive and negative electrons carried by free oxygen are not balanced, they need to be combined with oxygen molecules to generate ozone. Ozone has a strong oxidizing property and has a strong effect on removing malodorous gases. Generally, TiO2 coating will be added to the reaction chamber. Under the action of a catalyst (TiO2), ozone will oxidize the broken malodorous gas molecules into CO2 and H2O and other inorganic substances. For the waste gas that UV photolysis cannot decompose by ultraviolet light, it goes from the UV section to the activated carbon adsorption section. With the high adsorption of activated carbon, there is unbalanced and unsaturated molecular gravity or chemical bonding on the solid surface. When in contact with a gas, it can attract gas molecules, cause them to condense and remain on a solid surface. This phenomenon is called adsorption. By utilizing the adsorption capacity of the solid surface, the exhaust gas is brought into contact with the porous solid substance on the large surface, and the pollutants in the exhaust gas are adsorbed on the solid surface to separate it from the gas mixture, thereby achieving the purpose of purification.

two

· Features·

1. Modular integrated equipment, easy to operate at normal temperature and pressure

2.This technology can remove multi-component VOCs at the same time

3. UV photolysis technology is suitable for the removal of low and medium concentrations of VOCs, which requires very low energy consumption during work, and is used with non-energy activated carbon.

4, conventionally made of 304 stainless steel, the material can be selected from carbon steel, 201, 316L, etc.

5. High purification efficiency. The final products are H2O, CO and CO2. When the organics are chlorinated, chlorides should be added without other intermediate by-products, which reduces the toxicity of organics and avoids the problems of post-processing in other ways

6, excellent fire performance, the use of switches, power and circuit triple automatic protection function design

7. The equipment has beautiful appearance, exquisite volume, and convenient installation and maintenance.

Three

· Scope of application

1. Treatment of various harmful gases such as H2S, SOX, NOX, NH3, trimethylamine, methyl sulfide, methyl mercaptan, methyl sulfide, benzene, toluene, xylene, styrene and other odorous gases

2.Painting, spraying, ink printing, printing and dyeing workshop

3.Food, medicine, papermaking workshop

4.Treatment of exhaust gas from refineries, rubber plants, chemical plants, etc.

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!