-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

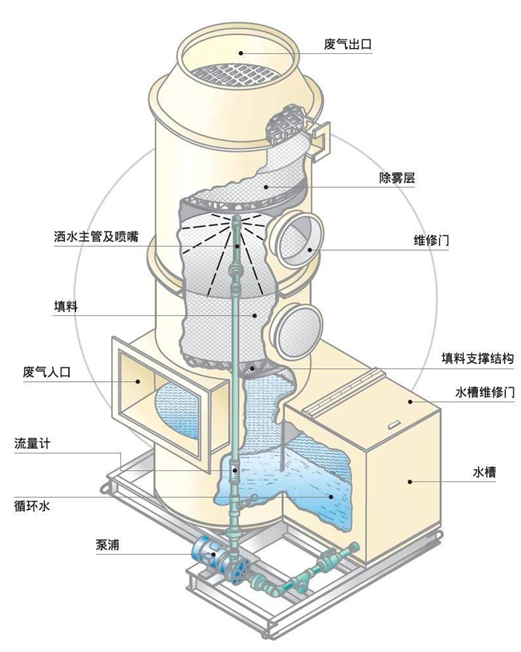

The square swirl tower is a kind of exhaust gas purification tower. Based on the principle of the original circular exhaust gas purification tower, our company independently developed the square swirl tower equipment with high purification efficiency, simple operation and management, and long service life. The process and product have the characteristics of low energy consumption, high purification efficiency and wide application range, and the height of the whole machine is greatly reduced compared to

TF series square swirl tower

The square swirl tower is a kind of exhaust gas purification tower. Based on the principle of the original circular exhaust gas purification tower, our company independently developed the square swirl tower equipment with high purification efficiency, simple operation and management, and long service life. The process and product have the characteristics of low energy consumption, high purification efficiency and wide application range, and the height of the whole machine is reduced compared to the circular spray tower, which is suitable for occasions where the height of the indoor or outdoor is restricted. Can effectively remove hydrogen chloride gas (HCL), hydrogen cyanide gas (NCN), hydrogen fluoride gas (HF), chromic acid mist (Cr03), ammonia gas (NH3), hydrogen sulfide (H2S), sulfuric acid mist (H2S04), alkali Water-soluble gas such as steam (NaOH) and formalin (HCHO), and can filter most of the dust contained in exhaust gas.

Product recommendation

fine

one

· Product principle ·

When the dust-containing gas with a certain inlet velocity enters through the air inlet pipe, the airflow first passes through a plurality of sets of swirling devices, and a spray device is installed above the swirling devices. The airflow and the absorption liquid make relative movement in the tower and rotate in the swirling The structure part of the flow tray plate forms a water film with a large surface area, thereby greatly improving the absorption effect. The flue gas is accelerated and swirled by the swirl pneumatic device in the absorption tower. The dust, dust, and the absorbent liquid collided, adhered, condensed, centrifuged and other comprehensive functions were thrown to the wall of the tower. The membrane flows to the bottom of the tower. Through the setting of the swirl pneumatic device, the number of rotations of the flue gas in the same height of the cylinder increases, the path it passes increases, the gas phase turbulence is severe, and the flue gas and the absorption liquid are fully collided, contacted, dissolved, and dissolved in time and space. absorb.

two

· Features·

1. Water-washing exhaust gas treatment system, with favorable price, simple treatment method, low operation and maintenance cost in the later stage

2. Square multi-spin fluid structure, suitable for indoor or outdoor space with limited height

3.Suitable for gaseous and liquid pollution sources

4. The opening rate of the tray is large, allowing high-speed airflow to pass, so the load is higher, the processing capacity is larger, the pressure drop is lower, and the operation flexibility is greater.

5. The setting of multiple swirl pneumatic devices makes the number of rotations of the flue gas within the same height of the cylinder increase, and the path of the gas flow increases.

The motion is violent, and the smoke and the absorption liquid are sufficiently collided, contacted, dissolved, and absorbed in time and space.

6. The box is made of 304 stainless steel or higher standard materials, which is durable. Filler adopts high-efficiency, low-resistance Bower ring, which can completely remove odors and harmful substances in the gas.

Three

· Scope of application

1. Treatment of various harmful gases such as H2S, SOX, NOX, HCI, NH3, CI2

2.Sewage treatment plant, waste landfill plant purification of exhaust gas

3.Semiconductor manufacturing industry, photoelectric industry, and other waste gas purification treatment

4. Treatment of exhaust gas from incinerators and industrial furnaces

5.Purification treatment of soot, acid, alkali, and malodorous gases discharged from printed circuit board industry, storage battery, dye manufacturing industry, etc.

6, especially suitable for indoor or outdoor occasions with limited height

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!