-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

WEM series products are characterized by the combination of wet and dry, large air volume, and integrated structure. Compared with other single filter dust collectors, the combination of wet and dry salient features is more specialized in special smoke treatment. Specially used for high temperature, oily, viscous, odorous or flammable and explosive smoke, avoiding the problem of filter clogging of dry filtration, and avoiding the problem of low filtration accuracy of wet filtration, and the whole machine includes a filtration

WEM series wet and dry integrated smoke purifier

WEM series products are characterized by the combination of wet and dry, large air volume, and integrated structure. Compared with other single filter dust collectors, the combination of wet and dry salient features is more specialized in special smoke treatment. Specially used for high temperature, oily, viscous, odorous or flammable and explosive smoke, avoiding the problem of filter clogging of dry filtration, and avoiding the problem of low filtration accuracy of wet filtration, and the whole machine includes a filtration system Integrated structure with fan system, small footprint, easy to move, high cost performance.

Product recommendation

fine

Product Principle

The filter system is a combination of wet and dry modes. Wet filtering uses water filtration at running cost. Special fumes and smoke can be added with specific agents (such as acid and alkali neutralization, and specific deodorants, etc.). When the smoke passes through the lower tank, the molecules and particulate pollutants collide with the mist droplets, and the droplets merge. Due to the larger surface viscosity of the oil molecules and particulate pollutants, they will be melted by the droplets. , The volume increases, causing sedimentation, so that the particle molecules in it are trapped by water. Because a small amount of water mist brought out by negative pressure has a greater impact on the next processing process, the treatment of water mist is also critical. Here, a combination of the first domestic traditional packing ball defogging and an improved high-temperature and corrosion-resistant gas-liquid separator is adopted. This gas-liquid separator adopts a circular design. In the layer and gas-liquid separator, water molecules and particles in the flue gas will cause turbulent collision due to inertia and centrifugal force. The water molecules and particles will be trapped after colliding on the channel wall, and the smoke will pass through the fine The steel wire is beaten out, and the processed flue gas becomes a low-humidity gas and enters the lower-level dry filter system.

Features

1. Wet and dry combination, specially designed for high temperature, oily, viscous, odor, or flammable and explosive dust.

2. Integrated design of filtering system and fan system, small footprint, easy to move.

3. A water mist isolator is designed between the dry filter and the wet filter to ensure that the water mist does not affect the service life of the dry filter.

4. The dry filtration is a multi-stage filtration structure. Coarse, medium, high efficiency and activated carbon filtration can be selected according to the properties of soot to ensure high filtration efficiency.

5. The wet filter structure uses the principle of vortex + surface water film adsorption, and the patented structural design highlights the significant role of pre-filtration.

6, can be installed according to the requirements of the installation of automatic water system.

7. Cleaners, thinners, medicine barrels, etc. can be installed according to working conditions.

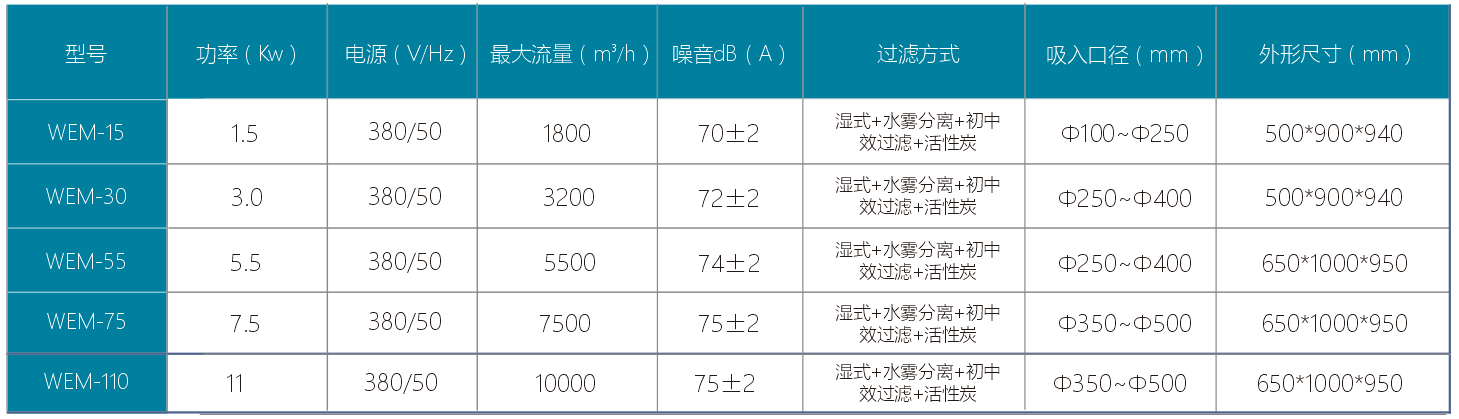

Scope and technical parameters

Diecasting, melting furnace, packaging printing, laser marking, cutting leather, non-metals such as PVC and other small amounts of dust + VOCs are processed nearby.

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!