-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

WP series products are characterized by cabinet structure, high negative pressure, and combination of wet and dry. Compared with other industrial vacuum cleaners, they are more professional. Suitable for vacuuming and cleaning of active metals such as aluminum, magnesium and zinc. Widely used in workshop vacuuming, 3D printing supporting vacuuming and other working conditions.

WP series high negative pressure wet dust collector

WP ( optional explosion-proof ) series products are characterized by cabinet structure, high negative pressure, and combination of dry and wet, which is more professional than other industrial vacuum cleaners. Suitable for vacuuming and cleaning of active metals such as aluminum, magnesium and zinc. Widely used in workshop vacuuming, 3D printing supporting vacuuming and other working conditions. One of the biggest advantages of the WP series is that it is completely suitable for extracting explosive substances or ultrafine powders.

Product recommendation

fine

one

· Product principle ·

The gas mixed with dust is sucked into the collection box filled with liquid, and the air, dust and liquid are fully mixed in the collection box. During the mixing process, the dust is dissolved into the liquid and finally precipitates on the bottom of the collection box. The convenient removal process of the dust collection box ensures that the sediment in the collection box is very easy to clean.

two

· Features·

1. Simple design ideas, high cost performance

2. In terms of power system, it adopts international advanced precision casting turbine fan (air pump-optional explosion-proof model), wide pressure dual frequency, high efficiency and reliability, low noise, long life, and can work continuously for 24 hours.

3. Independent control of electrical box, built-in thermal overload protection, optional phase sequence protection such as phase loss, reverse phase, etc. The control panel is simple and elegant, and can easily realize remote control, linkage control and other functions.

4. Multi-stage combined filtration in the filtration system. The first stage adopts wet filtration. The filtration medium is an emulsion of water, oil or various additives. The dust-containing gas is first passed into the liquid filtration medium, and a large amount of dust particles will be incorporated. Inside, avoid risks such as spontaneous combustion and explosion

5. The second stage adopts metal screen + coarse effect filter to form a second-stage filter. On the one hand, it suppresses the rise of water splashes, and on the other hand, isolates it from wet and dry to prevent water droplets and mist from entering the dry filter behind.

6. The last stage adopts H13 filtration level high-efficiency filter, which can filter 99% of the dust with a measuring diameter of 0.3μm or more, so as to capture the tiny dust particles escaping from the first two stages to achieve high-precision filtering.

7. Professional anti-leakage design to avoid water leakage in the application process. Acrylic perspective window design, dust and liquid contact water splashes.

8. Industrial-grade universal casters, top polyurethane material, easy and fast to move

Three

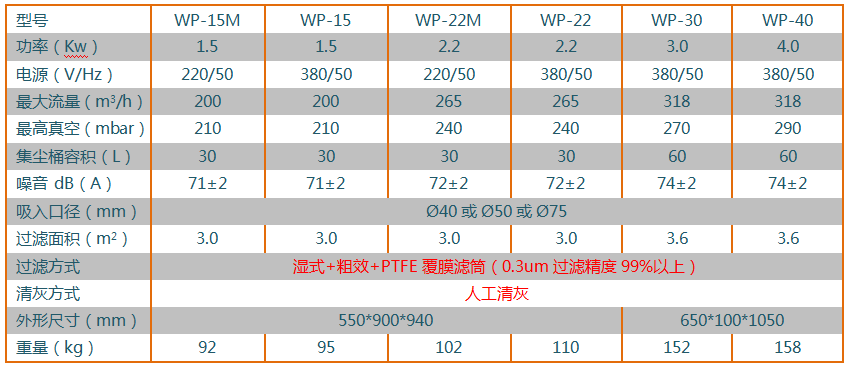

· Technical Parameters·

The following are the most reasonable and optimized size specifications comprehensively designed by our company based on detailed and parameter calculations and years of field experience of engineers. We can also customize the front water filtration device corresponding to the size specifications and materials according to customer requirements.

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!