-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Product center

ZDX series filter cartridges are characterized by filtering and pulse cleaning. The split structure can match high-power and high-air volume fans. Widely used in a large number of fine dust, multi-station operations, grinding, polishing, sandblasting operations, copper clad laminate processing, ceramic green embryo processing, calcium silicate board processing, wood board cutting, sanding, powder feeding, stirring, plating Tin packaging materials, capacitor spray welding, plasma cutting, etc.

ZDX series central dust collection system

ZDX series filter cartridges are characterized by filtering and pulse cleaning . The split structure can match high-power and high-air volume fans. Widely used in a large number of fine dust, multi-station operations, grinding, polishing, sandblasting operations, copper clad laminate processing, ceramic green embryo processing, calcium silicate board processing, wood board cutting, sanding, powder feeding, stirring, plating Tin packaging materials, capacitor spray welding, plasma cutting, etc.

Product recommendation

fine

Product Principle

ZDX series central dust collector, the main body is composed of the following components: upper box, injection pipe, storage cylinder, solenoid valve, venturi deflector, air inlet, spoiler, PTFE membrane filter cartridge, system box Frame, ash bucket and exhaust port

After the dust is collected through the suction inlets and enters the dust collector, the dust-containing air enters the filter room from the airflow equalization device of the dust collector, and first encounters the spoiler in the middle of the air inlet. Due to the sudden expansion of the air flow section and the Under the action, some coarse particles in the airflow settle in the ash hopper; when the airflow passes through the filter cartridge, the dust particles are filtered by the filter with a filtering effect of up to 99%, trapped on the surface of the filter cartridge, and fall into the ash hopper. Inside, the purified gas enters the clean room and is discharged to the workshop again through the exhaust pipe of the fan room above the dust collector. The principle is shown in Figure 1.

For sparks with sparks, a spark trap should be installed at the air inlet to prevent sparks from entering the filter room, and the filter is recommended to be equipped with a flame-resistant filter cartridge (that is, made of flame-retardant materials and will not burn)

Features

1.Power unit, stable and reliable

1.Power unit, stable and reliable

The fan unit adopts domestic famous brand fans (such as Jiuzhou Pratt & Whitney, Southern Fan, Infineon Fan, etc.).

The motor can be configured according to customer needs, high-quality motors such as Siemens and ABB.

Customers who have high requirements for noise can be equipped with a noise reduction speaker to isolate motor noise and reduce noise.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- -------

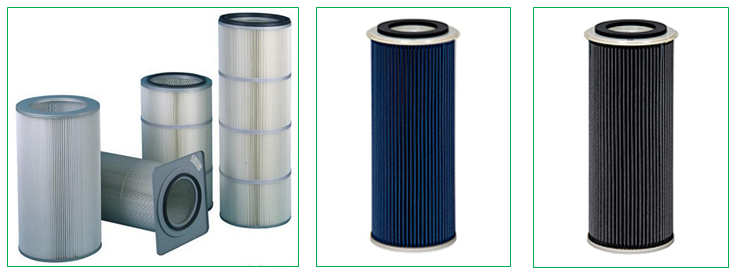

2.Filter cartridge filtration and quick release design

ZDX series central dust collection system, the filter unit is a cartridge filter, polyester fiber material, PTFE coating treatment, the standard configuration is Japan Toray "TORAY" substrate for PTFE coating treatment, single filter cartridge filtration area It is 20m2, and the filtering efficiency of dust above 0.3μm is more than 99%, and PTFE is not sticky with 99% of the world's substances, and it is more difficult for dust to adsorb the surface of the filter cartridge. Optional flame-resistant filter cartridge, anti-static filter cartridge, Donaldson filter cartridge, etc.

The installation of the filter cartridge adopts a vertical installation method. On the basis of ensuring the filtering area, it can effectively avoid the loss of the filter cartridge area caused by dust accumulation and the increase of the risk factor.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- --------

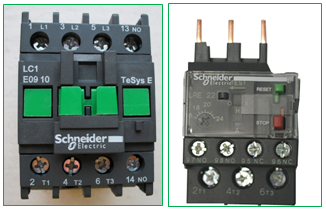

3. Electric control unit, quality assurance

3. Electric control unit, quality assurance

Electric control unit adopts famous Schneider brand, including AC contactor, thermal overload, circuit breaker, phase sequence protector, etc.

Can also be configured according to customer needs, Siemens, ABB, Mitsubishi and other brands.

It can also perform remote control, PLC control, touch screen panel, etc. according to customer requirements.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- --------

4. Pulse backflushing and dust removal, good effect

The pneumatic pulse blowback system consists of a cylinder, an electromagnetic pulse valve, a pulse controller, and compressed air. One end of the pulse valve is connected to a compressed air storage cylinder and the other end is connected to an injection pipe. An exhaust valve is installed on the valve cover, and the exhaust valve is controlled by a pulse controller.

When there is no signal from the pulse controller, the pulse solenoid valve starts to work, and each time the ash cleaning is completed at about 0.1 to 0.3S, it is the high-pressure air that is sprayed at this instant to play a good ash cleaning effect. Air enters the filter cartridge at a high flow rate, causing the filter cartridge to expand rapidly, causing an impact vibration, causing the dust attached to the filter cartridge to be shaken off, and the fine dust adsorbed on the surface of the filter material is shaken into the dust collecting bucket under the action of the airflow .

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ---------

5, the discharge unit

Stripper unit adopt a vertical bucket separation structure, when required discharge clean, stainless steel pull lever structure to collect the tub down, drawn, casters to the recovery position, can be dumped. After cleaning, close the empty bucket.

Can also be configured according to customer needs, using gas cap type, automatic discharge type and other modes.

Typical cases and parameters

long

press

turn off

Note

Guangzhou Puhua Environmental Technology Co., Ltd.

WeChat: PwC

Welcome to scan the code to customize your workshop exclusive solution

The boss stayed: waste gas treatment, dust treatment, oil mist treatment, overall ventilation of the factory. Welcome to leave a message.

Committed to industry-leading smart solution providers!