-

Factory Environmental Governance Comprehensive Solution Provider

-

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

Focus on R & D and manufacturing of VOCs exhaust gas treatment equipment

————— ◆ Comprehensive solution for laser processing of smoke and dust ◆ —————

>> Laser marking, laser cleaning

Laser marking laser marking metal and non-metal

1. Laser marking metal, which generates more metal dust, it is recommended to use a filter surface filter type smoke purifier, such as HTC / HCT series, with automatic dust removal function to avoid clogging of the filter. For marking aluminum-magnesium metal, explosion-proof design and production are also needed.

2. Laser marking of non-metals, such as laser marking of PVC, kraft paper, leather, IC cards / SIM cards, etc., will produce odorous smoke, and some are corrosive. HS / HC / HBC / HDC is recommended. Series of smoke purifiers with dust interception and odor elimination functions.

>> Laser welding, intersecting line cutting

1. The dust generated by laser welding is mainly high temperature dust and smoke. This type of dust mainly has the characteristics of small particle size, stickiness and high temperature. Due to laser welding, especially continuous welding conditions, high temperature gas inclusion sparks continue to be produced. It is easy to ignite the filter, creating a safety hazard.

2. In response to this working condition, Puhua Environmental Protection has developed a high-temperature, flame-retardant series of smoke purifiers with front spark traps to avoid burning out the filter.

3. For low-power laser welding, HC / HTC / HCT flame retardant configuration can be used, for continuous welding above 1kw, DG series flame retardant configuration is used, plus front spark trap

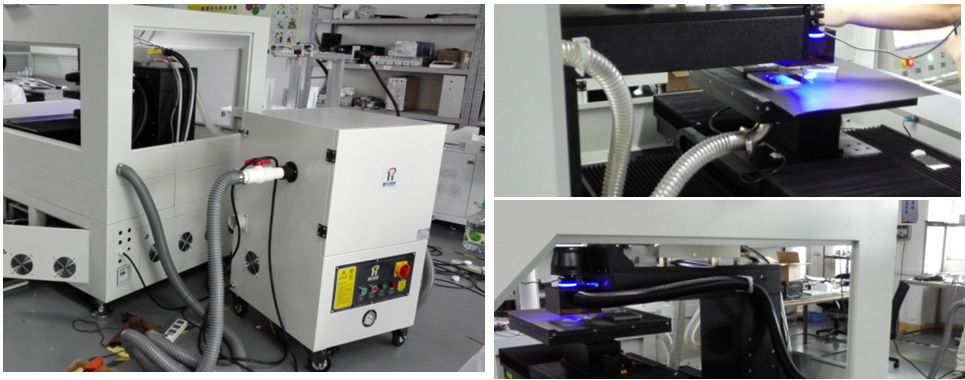

>>Laser cutting and adsorption

For small power laser cutting of FPC, pole piece, aluminum foil and other flexible sheets, it is necessary to first adsorb the cutting workpiece on the work surface and vacuum while processing. This requires a host to implement two functions. For this working condition, Puhua Environmental Protection has developed the DG series of high negative pressure and silent series industrial dust collectors with a power of 4.0kw which can achieve a noise lower than 72dB (A).

>> Laser cutting sheet metal

1. When laser cutting metal sheet metal, a large amount of dust and smoke will be generated. If it is not processed in time, it will cause environmental pollution and damage to the laser head. Generally, direct suction, blow suction, and damper vacuum are used for different types of dust extraction. In order to solve this problem, Puhua Environmental Protection has corresponding DF / DK series industrial dust collectors with different powers.

2. The DF series is a basic model with high cost performance, and the DK is an intelligent high-end model.

3. Our equipment has basically matched all the mainstream laser cutting machine manufacturers on the market, such as Han's, Falilai, Haimuxing, Xunlei, High Energy, Tianqi, Jiatai, Parkson, etc., corresponding to 3015, 4020, 6020 , 8025, 8030, 10035, 20040 and other specifications

>> Robot laser welding station

Robot / manipulator welding will generate a large amount of dust and smoke. If it is not handled in time, it will cause environmental pollution and damage to the laser head. Generally, direct extraction, blow suction, and damper vacuum are used. For different extraction methods, Puhua Environmental protection corresponds to industrial dust collectors with different powers of the DF series.

>> Laser cladding, regeneration

1. Laser cladding is a new surface modification technology. It adds a cladding material on the surface of the substrate and uses a high-energy-density laser beam to fuse it with a thin layer on the surface of the substrate to form an additive cladding layer on the surface of the substrate, which is a metallurgical combination.

2. Large ash is generated during the work. Due to most open operations, a flexible moving hood is required. Generally, the SE series with automatic ash cleaning function is used.

——————————————— ◆ Cooperation Process ◆ ———————————————